Roger Alder reflects on the demands of a job that can turn a reasonable person into an ogre.

When Shrek tells Donkey ‘Ogres are like onions—they have layers’, he hits on a key quality for anyone who has stepped out from behind a heavy tool box of well-polished spanners to take on the role of chief engineer. And to borrow another line from Shrek (the ogre hero of an animated Disney movie): ‘There is more to being a chief engineer than most people think’.

The position of chief engineer has evolved as part of Australian civil aviation maintenance culture, particularly in aircraft maintenance organisations approved by CASA under the provisions of Civil Aviation Regulation (CAR) 1988 regulation 30.

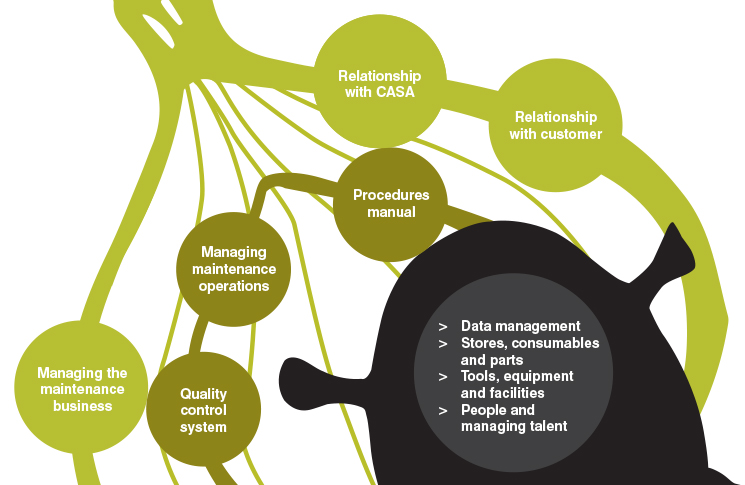

While there is currently no formal training, exam or recognition for someone who has this specific role, CASA has published guidance material in its Chief Engineers Guide, which contains a bewildering array of things that a chief engineer has to consider, and is arranged in … layers. The outer layer being high-level administration and customer relations, the next layer quality-control, and the inner core being a mix of nuts, bolts, split pins and team management.

A chief engineer’s lot includes managing:

- data—maintenance and airworthiness information

- tools, equipment and spares

- stores—consumables and parts

- people

- maintenance operations, including scheduling and estimating job times

- procedures, as required by maintenance manuals

- quality control, to be sure all jobs are safely completed

- customers

- the regulator’s requirements

- the business.

But no matter how the layers are arranged, it’s just a shopping list of tasks with no actual instructions on how to do them. CASA is providing some assistance via the AvSafety Seminars which, although geared for Part 145 aircraft maintenance organisations, would be very helpful for the CAR 30 engineers and chief engineers. But the thing is, you can do all the seminars and still not do the job properly. To try and discover some of the qualities of a good chief engineer, something not usually on the menu, we need to slice and dice an onion.

A good chief engineer is someone who can see through the various layers of administration, regulation, technology, logistics and human factors and how they interact, and yet is able to arrange them into meaningful priorities to ensure they work for safety, satisfaction and profit.

That’s a big call and a continually moving target. After long experience with aircraft hardware and systems, you now have to add both leadership and management skills. The transition can be very difficult. Some never quite make it.

‘Ogres are like onions?’ says Donkey, trying to get his head around the concept. ‘You mean they stink; they make you cry? Nobody likes onions. What about cake? Everybody loves cake! Cakes have layers.’ Donkey is appealing to a very determined Shrek to be more likeable, but Shrek will have none of it. ‘Ogres are like onions and that’s it! End of story.’

May I suggest that a key quality for any chief engineer is the ability to risk not being liked, or risk losing a client for taking—or even suggesting—an appropriate corrective maintenance action. You may be surprised to learn that many poor airworthiness decisions, which have resulted in injury and death, came out of the need to be ‘liked’ and to avoid conflict.

Fortunately, the framework for most airworthiness decisions has already been laid out for you, but another key quality of a chief—or any maintenance engineer for that matter—is knowing your way around all the various regulatory, technical and related operational requirements, sticking to the documented standards and to be able to bring others with you.

Big bad stress comes when battling with those who insist on unsound compromises to resolve the never-ending conflict between ensuring the aircraft will be in a condition for safe operation, and the cost of repairs and availability of the aircraft. A good chief engineer will learn to research a job before taking it on and not go solo when dealing with complex airworthiness decisions, unless you really have to. An important quality is the ability to manage the hangar resources and the client and know when to say ‘no’. Discussion with your engineering peers can bring new and helpful insights, and not needing to take the credit for a sound airworthiness decision is a quality most admired.

At this point let me introduce the highly acclaimed Safety Behaviours: Human Factors for Engineers resource kit from CASA. It comes in a surprisingly heavy little box which can be delivered to your hangar door. May I suggest when it arrives that you cut and peel back the outer layers, empty the box (preferably in a fairly confined area—you might actually need the other parts later), grab the main Resource Guide for Engineers book, and go straight to Chapter 10, Leadership.

Admittedly, you will not find the words ‘chief engineer’ anywhere in the entire package—but it’s a good starting point toward developing the key qualities of a good chief engineer, someone who can make sound decisions based on undisputable airworthiness and related operational data; who has the personal integrity that makes safety the first consideration without compromise, and can inspire others to do the same.

Well that’s an interesting read, albeit sterile and very 1990’s. Couple of observations. The Qualities of a Chief Engineer (dare I say responsible Manager) are varied and need to be taken seriously. Yes the ability to juggle data, stores, tools, people and do this whilst acknowledging and operating within the regulatory framework is pretty difficult. But there are a few things that make it difficult and for those who are thinking of aspiring to be a “Chief” one day some words of advice. First is the Company that employs you. At the end of the day the Accountable Manager holds the reigns and if they fail to uphold their obligations then it makes the job of Chief Engineer almost impossible.

CASA have a part to play here and they are right about there being no special “training Course” or guidelines for being a Chief Engineer but there should be (as there should for an Accountable Manager). Progression up the Pilot or Engineer “ladder” is not enough. Aviation in Australia is plagued by organisations with Managers that have zero ability (good intentions)but no people or business skills. The best that CASA can muster is a to get Form 4 (approved person forms). All we end up with is bureaucratic red tape and zero actual good or robust framework for people to execute in these key positions.

If you are an Engineer in Aviation… heed this advice. Go out and do your License Exams, get rated, do all those engine and Avionic courses. That is important but…. Where most Engineers go wrong is thinking that their License and their ratings is the key to opening all doors. Yes its a good start but in this global aviation community you need to be knowledgeable and skilled in many things to give you an edge. Not only to get a job but to stay relevant and to be a contributor to aviation safety, not a hindrance to it. I have been in a few aviation workplaces and turn-over, lack of engagement, absenteeism, negativity are rife in hangars where limited Managerial talent is present. Nobody wants to work in these places.

No business can afford to employ all the specialists they need. Aviation is not just about pilots and Engineers… its about people with a knowledge (and interest) in all the other “boring” pursuits that make up an aviation workplace. This includes HR, Human Factors, Hazard identification and Risk Management, Project Management, Scheduling and Planning, Safety Investigation, WH&S, Regulatory Compliance, Governance, Training etc etc. The list is endless. So whilst you may not think it sexy or relevant I am here to tell you it is. Go and do a Cert IV or Diploma in Management (you will learn a few things), do some training in Business or Project Management, Finance, Risk Management….. in aviation its all relevant and it will give you skills to be a good “Chief” that people respect and want to work for.

All you Accountable Managers, ask yourself this simple question…. “What have I done to facilitate the training of my people / the Industry as a whole”? If you have no reasonable answer to this question it’s time for you to hand in your Accountable Managers Hat. Safety does not tolerate averageness, neither should the Industry as a whole.

Excellent advice and knowledge sharing. You hit the nail on the Head Gavin.