Beech 200 Beech Hydraulic system main—hydraulic line loose and leaking. SDR 510020139

Small hydraulic leak from RH main landing gear up line. The fitting was found to be slightly loose.

Beech 200Beech Landing gear position and warning system—microswitch suspect faulty. SDR 510020172

Landing gear down microswitch suspect faulty. P/No: 1013646281.

Beech 200Beech Pitot/static system—pitot line worn. SDR 510020171

Pilot’s and co-pilot’s air speed indicators had variable split of 4 to 15 knots. Investigation found instrument air line in co-pilot’s pitot system chafed.

Beech B95 Fuel storage—fuel cell ruptured. SDR 510020063

Fuel leak found during daily inspection from right-hand gear door. Fuel cell found ruptured. P/No: 583800036. TSN: 7055 hours/360 months.

Britton Norman BN2 DC generator-alternator—alternator unserviceable. SDR 510020201

Prior to fitting to aircraft, the newly purchased alternator was spun over and a grinding noise was noticed. Suspect rotor rubbing on stator. P/No: ALT8521R.

Cessna 172N Nose landing gear strut/axle—axle cracked. SDR 510020196

RH main landing gear axle cracked beneath paint. Crack length approximately 25.4mm (1in) internally. Found during SIDs inspection. P/No: 05411991.

Cessna 208 Engine mount section—mount corroded. SDR 510020165 (photo above)

Cessna 208 Engine mount section—mount corroded. SDR 510020165 (photo above)

LH lower engine mount corroded. See also SDR 510020164. Aircraft had operated on floats at some time during the past. P/No: 26130877. TSN: 5020 hours/192 months.

Cessna 208 Nacelle/pylon bulkhead/firewall—bulkhead corroded. SDR 510020164 (photo above)

Cessna 208 Nacelle/pylon bulkhead/firewall—bulkhead corroded. SDR 510020164 (photo above)

Lower firewall bulkhead corroded. Found following removal/replacement of firewall lower forward doubler PNo 2653037-1. Lower LH engine mount PNo 2613087-7 also replaced due to corrosion damage. Aircraft had operated on floats at some time during the past. P/No: 26530371. TSN: 5020 hours/192 months.

Cessna 210L Wing spar—spar corroded. SDR 510020181

Carry through spar corroded beyond repair. Found during SIDs inspection.

Cessna 210M Landing gear retract/extension system—guide damaged. SDR 510020110 (photos above)

Cessna 210M Landing gear retract/extension system—guide damaged. SDR 510020110 (photos above)

Nose landing gear downlock guide bent due to fitment of incorrect downlock spring. P/No: 98820241.

Cessna 210 Nose landing gear attach section—trunnion broken. SDR 510020098

Nose landing gear trunnion broken in area of attachment to nose leg. Crack has been developing for some time. SID 32-20-02 not due until 30/06/2015. Investigation continuing. P/No: 124340215.

Cessna 404Cessna Nacelle/pylon plates/skin—nacelle damaged. SDR 510020099

R/H Nacelle lower skin found torn behind ram air inlet. P/No: 0322024T42ALCLAD. TSN: 13585 hours/25300 cycles.

Cessna 441 Air distribution system—shutoff valve unserviceable. SDR 510020203

Pressurisation system LH and RH bleed air firewall shutoff valves unserviceable. P/No: 72023RX.

Cessna 441 Engine oil storage (airframe)—filler cap damaged. SDR 510020204

RH engine oil filler cap damaged and deformed causing cap to crack. Loss of oil pressure caused engine to be shut down. P/No: 31030111.

Cessna 441 Landing gear position and warning system—microswitch unserviceable. SDR 510020072

On landing, NLG failed to indicate if the NLG was down. ATC advised that the landing gear was down. AC landed without incident. Investigation found that the wiring in the NLG micro switch had been removed. P/No: 1CH16.

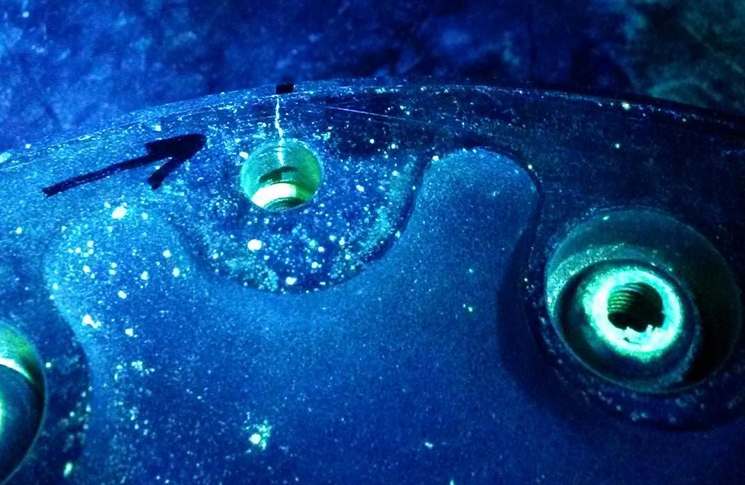

Cessna 441 Wheel—wheel cracked. SDR 510020170 (photo above)

Cessna 441 Wheel—wheel cracked. SDR 510020170 (photo above)

Main wheel inboard hub cracked from tie bolt hole. Crack length approximately 16mm (0.62in). Found during fluorescent penetrant inspection. P/No: 40169.

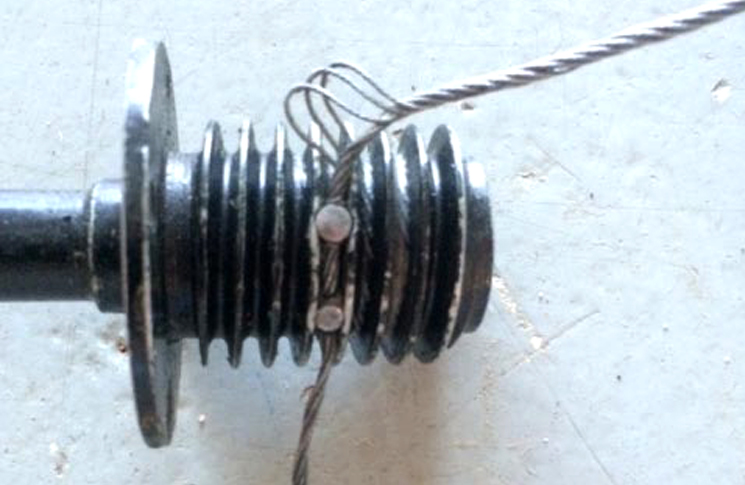

De Havilland DHC1 Elevator tab control system—trim system worn and damaged. SDR 510020071 (photo above)

De Havilland DHC1 Elevator tab control system—trim system worn and damaged. SDR 510020071 (photo above)

Elevator trim cable found worn and damaged with several broken strands in area of forward trim wheel due to incorrect installation. P/No: C1CF349A. TSN: 381 hours.

Gippsland Aeronautics GA8 Pitot/static anti-ice system—terminal block incorrect fit. SDR 510020066

During Scheduled maintenance it was noted that the terminal block for the pitot heat, located at the LH wing tip, had previously been installed incorrectly and one wire was also broken at the ring terminal.

Kavanagh B400 Balloon reports—load frame cracked. SDR 510020137

Balloon load frame cracked. Suspect caused by fatigue when balloon is being transported by trailer to launch/landing sites. P/No: KLF201088CBS.

Partenavia P68B Engine mount section—mount cracked. SDR 510020118 (photo above)

Partenavia P68B Engine mount section—mount cracked. SDR 510020118 (photo above)

Lower LH engine mount attachment lug cracked. Found during inspection iaw AD/P68/3. P/No: 6862003B. TSN: 9727 hours.

Partenavia P68B Engine mount section—mount cracked. SDR 510020119 (photo above)

Partenavia P68B Engine mount section—mount cracked. SDR 510020119 (photo above)

Engine mount frame cracked at lower weld cluster. Found during inspection iaw AD/P68/3. P/No: 6862003B. TSN: 20757 hours.

Partenavia P68B Nose landing gear strut/axle—pin lock distorted. SDR 510020121 (photo above)

Partenavia P68B Nose landing gear strut/axle—pin lock distorted. SDR 510020121 (photo above)

Nose landing gear oleo cylinder unscrewed from upper piston causing metering pin to be misaligned and bend. P/No: 6842035B1. TSN: 20757 hours.

Piper PA28R201 Landing gear retract/extension system—rod end cracked. SDR 510020070

Nose gear extended in flight due to rod end Part # 452-729 separating hydraulic actuator from retract mechanism. New rod end fitted and retracts carried out. Nil defects. P/No: 452729.

Piper PA31 Landing gear door actuator—rod end corroded. SDR 510020193

LH main landing gear door actuator link rod end bearing corroded. Rod end fractured in threaded area. Aircraft had been stored outside in the weather and had not been flown for approximately seven months. P/No: 452383.

Piper PA31 Landing gear retract/extension system—downlock hook corroded. SDR 510020194

LH main landing gear downlock hook corroded and dry. Aircraft had been stored outside in the weather and had not been flown for approximately 7 months. P/No: 4198300.

Swearingen SA227AC Autopilot trim servo—clamp undertorqued. SDR 510020094

During pre-flight checks, pilot reported the control column was only able to move a few inches (jammed). Investigation found the Autopilot Pitch Servo Bridle Cable Loose and the RH bridle clamp block bolts found under torqued. P/No: 6121.

Swearingen SA227AC Autopilot trim servo—trim servo unserviceable. SDR 510020168

Autopilot system pitch trim servo operating in reverse sense. Investigation found the pitch servo trim sensor wires may have been transposed. Investigation continuing. See attachment for initial investigation details. P/No: 01230P9. TSO: /16 landings.