Honeywell various parts SUP. SDR 510022781

Reference Honeywell Quality Assurance Memo CSB—107008. Honeywell discovered that they received suspect electronic counterfeit parts from two suppliers (the ‘Suspect Counterfeit Parts’) and that these parts have been assembled into delivered products. Honeywell severed relationship with the suppliers, purged their inventory of the Suspect Counterfeit Parts and initiated fielded product impact assessments. Honeywell’s preliminary assessment indicates no immediate safety of flight conditions exist; therefore, Honeywell recommends continued use of all products that may contain these parts. Six similar reports received. P/No: 20411687513.

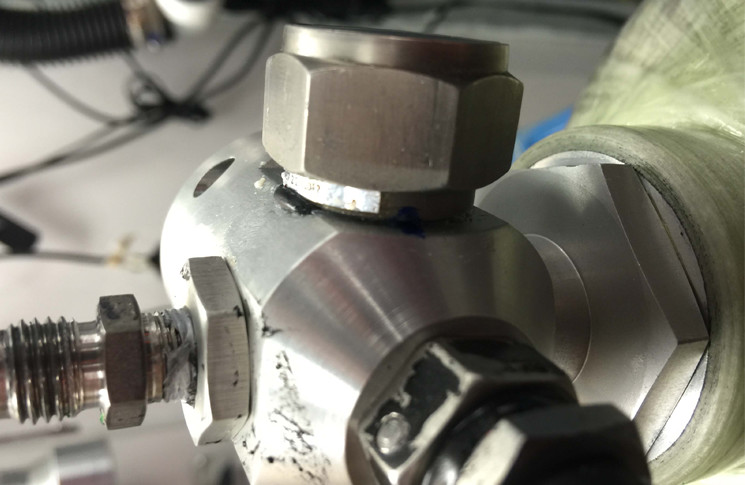

Air Cruisers Div Of Garrett Corp 64356101 packing damaged. SDR 510022860 (photo above)

Air Cruisers Div Of Garrett Corp 64356101 packing damaged. SDR 510022860 (photo above)

Life raft was removed after being noticed having a low inflation cylinder pressure. Root cause identified as failure of O-ring between pressure indicator and valve assembly. New O-ring was installed taking it from different batch and stock. Consultations underway with the OEM. P/No: B14056907.

Hot air balloon Load frame cracked. SDR 510022806

Minor hairline cracks were discovered along welded joints during a periodic inspection. The manufacturer is aware of the problem and has included it in the 100 hourly inspection. Three similar defects reported. P/No: KLF201088CBS. TSN: 464 hours/17 months.

Magneto damaged. SDR 510022714

LHE RH Mag Distributor Block failed Continental SB 669 Alternate procedure test. Distributor gear bushing found unbonded allowing the distributor gear & bush to rock through approximately 15 degrees. This failure is described in CASA AWB 74—005 Section 3.3 & figure 5. Distributor bearing block was replaced new on last 500 Hourly Mag Inspection and has only done 180.1 Hr since new. P/No: 103492607. TSO: 848 hours/1540 cycles/39 months.

Shell Water Detection Capsule 3502 fuel nil indication. SDR 510022738

A water detection sample test was performed prior to receipt of fuel from the tanker. Fuel was drawn through the Shell Water Detection Capsule with no indication showing of water present. The person performing the test applied a small amount of spittle IAW Company Local Procedures to simulate the presence of water. The capsule however did not change from yellow to blue as it should have. Another capsule from the same container and batch was again tested with the same result. The two capsules were then submerged under a running water tap with no change in indication. The test was then conducted with a different batch with an immediate change to blue indicated.