| ROTORCRAFT | ||

| ROBINSON R22 BETA – ATA 2823 FUEL SELECTOR/SHUTOFF VALVE – SHUTOFF VALVE – CRACKED. DR 611953799 | ||

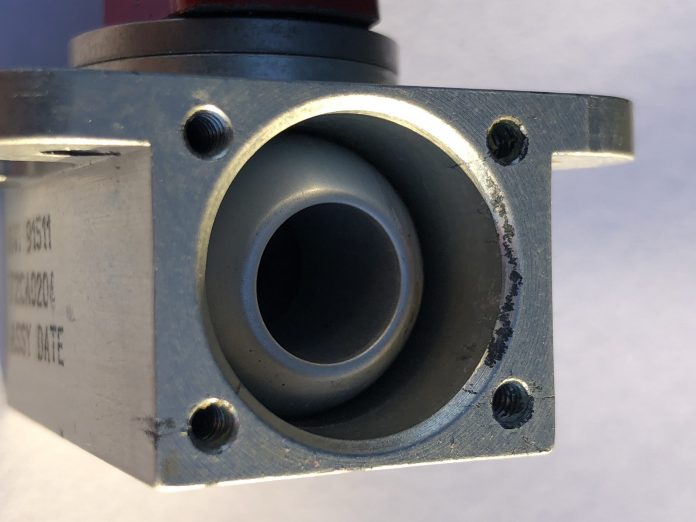

| Fuel shutoff valve assy A670-1 found to be having multiple cracks where stainless steel inlet plate attaches to valve aluminium body. Cracks are located around the SS screw locations.

Root cause: Suspect dissimilar metal corrosion. Part replaced with new item. |

||

| AGUSTA AW189 – ATA 3230 LANDING GEAR RETRACT/EXTENSION SYSTEM – HYDRAULIC LINE – RUPTURED. DR 611953842 | ||

| In flight, hydraulic failure with CAS HYD UTIL PRES illuminated.

Root cause: NLG ‘UP’ hydraulic line had developed a leak in between the shielding and the swage. Leaking hydraulic oil was atomized and found its way into the cockpit/cabin area.NLG ‘UP’ hydraulic line was removed and replaced with a serviceable item. |

||

| ROBINSON R44 II – ATA 6230 MAIN ROTOR MAST/SWASHPLATE – BEARING – FAILED. DR 611953855 | ||

| While inspection, drivetrain was difficult to rotate. Root cause: Upper mast bearing lubrication failure. Transmission assy removed from service for rectifications. |

||

| AGUSTA AW139 – ATA 6700 ROTORCRAFT FLIGHT CONTROL – Guidance Controller – LOOSE CONNECTION. DR 611953863 | ||

| Following an auto-hover, Transition Up (TU) was selected suing the Go Around (GA) button. The aircraft was very slow to accelerate with the aircraft oscillating in pitch by approximately 5 degrees. At approximately 200ft AGL, the aircraft captured hover mode with no Pilot input to select it. The nose pitched up and the PF had to fly manually to overcome the nose high attitude. A return to base was initiated.

Engineering carried out an operational test of the cyclic beep switches and cleaned the electrical connectors on the Guidance Controller. The cyclic and collective functions were checked and adjusted as required. |

||

| BELL 412 EP – ATA 6720 TAIL ROTOR CONTROL SYSTEM – SERVO – UNSERVICEABLE. DR 611953867 | ||

| During 4th 25 hrs inspection, black fretting was found coming out between the servo rod and body of tail rotor servo P/N 212-076-004-103. This was not a part of inspection however, LAME observed it while working in the surrounding area. Upon further investigation it was found that the attachment bolt was also turning. The following investigation / remedial action was undertaken: 1. Unserviceable tail rotor servo was replaced with serviceable one. 2. Documentation check revealed that the servo was installed 89.3 hrs prior. The servo failed at TSN 89.3 hrs. 3. Bell 412 PSE Medium (Type certificate holder) was approached and notified the defect. 4. Technical representative advised that the hardware retaining the piston inside the servo was an expendable bolt and has a torque value. 5. Unserviceable Tail servo is being dispatched to Bell 412 for strip examination and further investigation. 6. Aircraft was released to service after replacement of faulty servo and follow on maintenance |

||

| ROBINSON R22 BETA – ATA 6720 TAIL ROTOR CONTROL SYSTEM – Rudder pedals – SHEARED. DR 611953876 | ||

| Helicopter was conducting mustering operations approx. 250 ft AGL when at the end of run, while applying R/H pedal, weld snapped resulting in loss of control with no other indication. Various pilots have admitted to pushing themselves back into seat using pedals (probable cause), measures have been put in place, to c/o MPI of pedals @ 2200 hours inspection. | ||

| AGUSTA AW189 – ATA 2421 AC GENERATOR-ALTERNATOR – GENERATOR – FAILED. DR 611953877 | ||

| In flight, observed CAS message BUS TIE CLOSED shortly followed by FWD AIRCON FAIL. TCAS/XPDR alternating between TA/RA & ALT ON.

Approx. 2 minutes after initial indications, CAS message 2 AC GEN HOT with associated HOT above #2 GEN symbol on MFD. Initiated return to base. All non-essential busses re-powered. AC Generator fail. Generator replacement required. |

||

| ROBINSON R44 – ATA 6210 MAIN ROTOR BLADES – MAIN ROTOR BLADE – DEBONDED. DR 611953882 | ||

| On carrying out 100 hourly inspection, noticed a bubble at tip of main rotor blade. On removal of corrosion bubble, blade was found to be delaminated about 1m from the tip. | ||

| EUROCOPTER AS350 B2 – ATA 6220 MAIN ROTOR HEAD – BEARING – WORN. DR 611953890 | ||

| Starflex Assembly bush wear beyond acceptable limits. Allowable limits: 0.1mm differential across bush length. Replace/repair starflex assembly and starflex bearings. |

||

| AGUSTA AW139 – ATA 2590 NON STANDARD EQUIPMENT SYSTEM – Windscrew – DAMAGED. DR 611953925 | ||

| During scheduled 30-day hoist inspection, 180 feet of cable had been reeled out when the winch ceased reeling and the operator noticed the cable foul indication on the hoist pendant. CAS message on the aircraft was also noticed at this time.

Cable foul light subsequently extinguished and operator was able to winch for a further 3 feet / 1 second (approximately) before cable foul returned. Aircraft power was recycled, the cable foul light remained off but the hoist would not operate. The hoist cowl was then removed, and misalignment of the hoist cable discovered. The cable was 6-7 wraps out of alignment with the drum and cable guide. Upon subsequent visual investigation, it was discovered that a section of the level wind screw missing, an adjacent section of the level wind screw deformed, and two metallic fragments were found in the cable drum housing area. There is no obvious indication as to the cause of these conditions. |

||

| KAWASAKI BK117 B2 – ATA 5320 FUSELAGE, MISCELLANEOUS STRUCTURE – DOUBLER – CRACKED. DR 611953927 | ||

| During routine maintenance, missing rivet heads were noticed on the airframe hoist attachment doubler in two locations.

Upon deeper investigation, two attach doublers inside the airframe structure were found to be cracked. Poor installation and fatigue were thought to have contributed to the cracking. The cracked doublers were remanufactured IAW, AC43 and Standard Practices Manual. The STC holder has been advised and a Service Letter has been issued to inspect this area. |

||