Researchers at Embry-Riddle Aeronautical University in Florida, US, have developed a way to place nano-scale piezoelectric sensors, directly onto carbon fibres.

The zinc-oxide nanowire sensors generate an electrical charge in response to different levels of mechanical stress.

The nanowires also strengthen composite materials, Embry-Riddle Professor of Aerospace Engineering Marwan Al-Haik, said. He said building larger fibre-optic sensors into composite materials as sensors could cause cracks and delamination of materials.

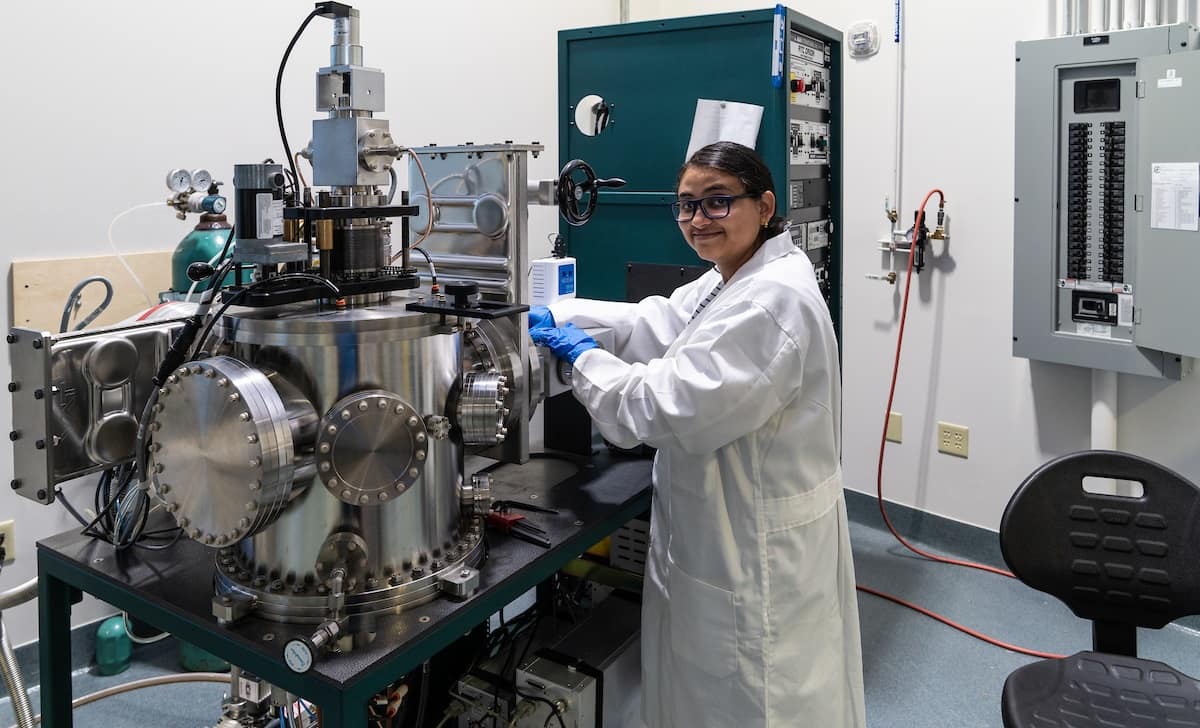

The technique uses a vapour deposition machine that makes it possible to precisely deposit up to five materials at the same time on a thin substrate. Operating under extremely low vacuum pressure—100,000 times less than atmospheric pressure—the machine can put tiny films onto different substrates.

Researcher Suma Ayyagari said the vapor deposition process was like growing tiny plants. ‘Basically, you deposit some seeds and add a kind of fertiliser,’ she said. ‘You need wet chemistry to grow the seeds.’

Al-Haik said, ‘A human hair is around 25 microns, and we’re working on a scale that’s one ten-thousandth of that.’

Built in structural monitoring would have potential to improve aviation safety by instant detection of structural issues.

‘Airlines could wirelessly receive data to continuously monitor their fleet,’ Al-Haik said. ‘Our hope is that, after we get that correlation between defect size and electrical signal, if it’s a crack length that exceeds, let’s say 5 millimetres, a signal would be sent to an operator on the ground. That person would say, “Uh oh, that’s the 747 and it’s in wing. We’d better take a look at that right away.”’