An observant and quick-thinking helicopter pilot probably saved their life by landing soon after noticing unusual vibrations. A subsequent inspection of the Robinson R22 Beta found a crack in one of the main rotor blades that went almost entirely through its cross-section.

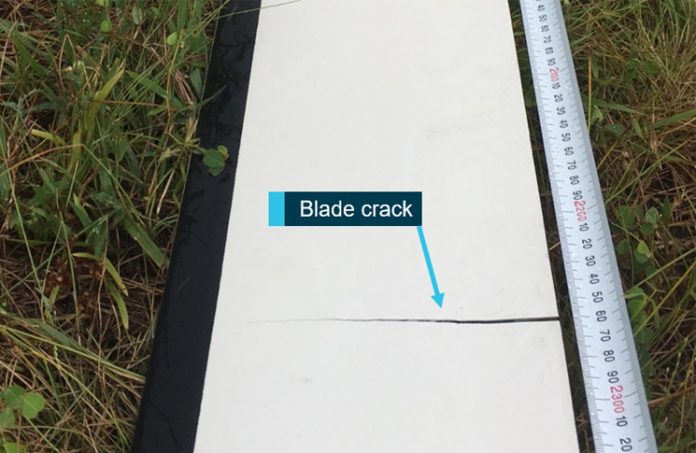

The incident took place in December 2016 during a cattle mustering flight in the Northern Territory. The Australian Transport Safety Bureau’s (ATSB) investigation confirmed an extensive chord-wise crack had propagated from the blade’s trailing edge through both the upper and lower skins, stopping just short of the leading edge D-spar.

The investigation found no initiating or contributing defects such as corrosion pitting, external damage, deformation or metallurgical anomalies in the blade skins.

However, the helicopter’s flight records showed in December 2014 it had sustained a heavy landing and a suspected main rotor overspeed after losing tail rotor control. ‘The incident necessitated blade removal and inspection,’ the report says. ‘After the blades were inspected and the spindles repaired, they were returned to service. Both blades were operated for an additional 778 hours up until the failure, accumulating 1794.7 hours total time in service, well short of their life-limit of 2200 hours.’

The ATSB says it is possible the heavy landing overstressed the rotor system and, in combination with its mustering usage, produced a level of fatigue damage that was not detectable during the blade inspection. But it stops short of a firm conclusion, saying the ‘potential damage was unable to be quantified by the investigation, and it could not be concluded that the operation-type or previous damage sustained was a contributing factor to the blade cracking.’

The report could not determine if early signs of cracking could have been detected at the aircraft’s last 100-hourly inspection. It says several factors made it harder for beginnings of a crack to be detected in the aircraft’s daily inspections. Inspection instructions are non-specific and black paint on the underside of the blades would have combined with blade droop at rest to possibly conceal the fine detail of the crack features.

The ATSB endorsed the pilot’s decision to land. ‘Had the pilot elected to continue operating the helicopter, there was an increased potential for an in-flight loss of control due to further deterioration of the blade aerofoil surfaces,’ it says.

Official response was swift. Eight days after the incident, the Robinson Helicopter Company issued a Safety Alert that recommended close visual inspections of the trailing edges of blades during daily pre-flight inspections. In February 2017 Robinson made a minor redesign of the rotor blades. CASA issued Airworthiness Bulletin 62-006 ‘Alert – R22 Main Rotor Blade Cracking’ (Appendix B) nine days after the incident. The operator spoke with its aviation staff about the importance of following manufacturer’s recommended procedures for conducting the daily and pre-flight inspection of the main rotor blades, and the need to land immediately should unusual vibrations increase or develop during flight.