Airbus A319-132 Oxygen system—oxygen generator unserviceable. SDR 510021555

Oxygen generators removed and replaced IAW EASA AD 2015-0117. 38 oxygen generators replaced (31 activated correctly, seven failed). P/No: 1170420211704204. TSN: /144 months

Airbus A320-231 Autoflight system—autopilot suspect faulty. SDR 510021831

Five minutes after take-off, autopilot auto disconnect and N1 Mode alerts both engines.

Airbus A320-232 Air distribution fan—recirculation fan seized. SDR 510021675

Aft cabin fan amber on cond page, electrical smell throughout cabin and flight deck for approximately 5minutes. Found CB tripped on fan 2. Investigation found that the recirculation fan FIN 14HG seized. Fan replaced and tested OK.

Airbus A320-232 Air distribution system—APU overfilled. SDR 510021632

On ground preparing for engine run, cockpit and forward galley filled with smoke for a duration of approximately 10 seconds, the smell was described as an electrical burning smell and persisted for several minutes. APU oil level found high, oil level adjusted. No other defects found.

Airbus A320-232 Crew station equipment system—seat belt disengaged. SDR 510021834

During climb, the captain noticed that the seatbelt had detached from the left hand side of his seat.

Airbus A320-232 Equipment/furnishings wiring—oven odour. SDR 510021549

Aircraft diverted due to fumes in the rear of the cabin. Musty burning smell. Dirty oven cause of smell.

Airbus A320-232 Exterior lighting—landing light unserviceable. SDR 510021754

On daily walk around RH landing light bulb, retaining ring and gasket missing, one lamp lug remained attached to lamp electrical loom and scratched underwing surface. RH landing light was replaced and tested serviceable in previous sector. P/No: Q4559X.

Airbus A320-232 Flight compartment windows—windshield cracked and arcing. SDR 510021492 (photo above)

During cruise, outer pane of FO’s windshield experienced arcing and cracked. Investigation ongoing. P/No: NP1653118. TSN: 16837 hours/9637 cycles

Airbus A320-232 Galley station equipment system—oven odour. SDR 510021857

Fume event from aft galley ovens. Odour dissipated when ovens were turned off. Both ovens replaced.

Airbus A320-232 Hydraulic pump main—pump unserviceable. SDR 510021709

Loss of blue hydraulic system in cruise. Engineers confirmed fault was a failed blue electric pump and replacement was carried out. P/No: 5115404. TSN: 24525 hours/14274 cycles

Airbus A320-232 Independent position determining system—proximity unit suspect faulty. SDR 510021740

NAV GPWS fault in flight. Engineering performed troubleshooting. No response from GPWC during bite attempt—fault light on both overhead panels switches. GPWC CBs tripped and reset. Bite test carried out satisfactory IAW AMM. P/No: 9651676003. TSN: 6714 hours/4053 cycles

Airbus A320-232 Master cylinder/brake valve—transducer unserviceable. SDR 510021753

Diversion due to alt break release fault. Troubleshooting found pressure transducer u/s. Replaced transducer and operational test carried out satisfactory of ALT brake system. Fault came back after replacing the transducer. Following TSM and servo valve 97 GG (PN E21330000-1) required replacement. Servo valve replaced IAW AMM. Operational test carried out satisfactory of ALT brake system. Nil faults or hydraulic leaks. P/No: CZ9DM6AANDE213300001.

Airbus A320-232 Navigation system—transceiver incorrect configuration. SDR 510021808

Basic Rad ALT transceiver part number 066-50007-0432, S/N: ALA52B-06188 was incorrectly identified as a 066-50007-0222 unit. This unit was issued to the aircraft and installed. The aircraft was grounded upon discovery and the correct RAD ALT transceiver P/N was installed.

Airbus A320-232 Passenger station equipment system—PSU burnt. SDR 510021692 (photo above)

Electrical smell reported from aft cabin area. Row 25ABC, passenger service unit found electrically burned / shorted. P/No: Z315H2000110.

Airbus A320-232 Wing control surface attach fittings—flap track corroded. SDR 510021673

Significant corrosion has been identified at the forward end of the mounting plate of Flap Track 2 near Rib 6A. Corrosion is current being reviewed in consultation with the Aircraft OEM.

Airbus A320-232 Wing plates/skin—skin corroded. SDR 510021704

During 7C Check, extensive corrosion found on the wings.

Airbus A320-232 wing plates/skin—wing corroded. SDR 510021705

Extensive corrosion found on LH wing top skin panel 1 & 2 during 7C check. Permanent repair carried out at these locations as per Airbus Technical Disposition.

Airbus A321-231 Wing plates/skin—skin corroded. SDR 510021801

Corrosion damage found at left hand wing top skin T/E overhang at multiple locations during 10C check.

Airbus A330-201 Trailing edge flap actuator—strut loose connection. SDR 510021731

Flaps locked, investigation revealed R/H track-2 drive strut forward and aft eye end not secured. Locking keys sheared off and evidence of barrel rotation.

Airbus A330-202 Aircraft fuel distribution system—fuel line chafing. SDR 510021826

After landing, a significant leak of fuel from beneath the reverser cowl of No. 2 engine was noted. Upon engineering investigation, it was found that a clamp to the left side fuel manifold had chaffed the fuel line at the engine’s 6 o’clock position. P/No: 2420M70G01. TSN: 43354 hours TSO: 15586 hours

Airbus A330-202 Emergency exits—seat belt screw missing. SDR 510021634

Seatbelt came out of housing, three screws found missing from seat pan slide carriage assembly.

Airbus A330-202 fire bottle fixed—extinguisher empty. SDR 510021796

Toilet fire extinguisher found with nil pressure, fusable tip found distorted and ruptured. P/No: BA24320A1. TSN: 5398 hours TSO: 1697 hours

Airbus A330-202 Passenger station equipment system—seat loose. SDR 510021481

Cabin crew reported passenger seat wobbly in flight. The seat’s aft mount were not secured down.

Airbus A330-203 Crew oxygen system—hose broken. SDR 510021624

During scheduled detailed inspection of the Zone A oxygen masks, it was noted that a hose to one of the two masks fitted at the Door 1R (fwd) position had broken and detached at the oxygen generator spigot. P/No: E6068100.

Airbus A330-243 Air conditioning system—aircraft interior odour. SDR 510021752

Cabin crew reported unusual odour around the mid galley (door 2 area) described as a little oily/body odour smell. Troubleshooting carried out and no smells could be reproduced on the ground.

Airbus A330-243 aircraft fuel distribution system—pump low pressure. SDR 510021475

During cruise, flight crew reported low pressure in L2 fuel pump. Pump reset carried out and returned to normal. Operational test of the main fuel pump carried out satisfactorily. Nil defects found.

Airbus A330-243 APU cowlings/containment— APU auto shutdown. SDR 510021786

During application of MEL for trim tank isolation valve inoperative, APU shutdown occurred. APU fuel line bleed carried out. P/No: 38004546. TSN: 6195 hours/5206 cycles

Airbus A330-243 APU oil system—APU contaminated metal. SDR 510021630

APU lubrication and Generator scavenge filters contaminated with non-magnetic metallic debris. Samples collected and sent for analysis. P/No: 38004546. TSN: 6704 hours/5395 cycles

Airbus A330-243 APU system—cabin odour. SDR 510021734

Crew reported oil smells evident after APU start and selection of APU bleed on the ground prior to boarding. Smell noted again between 7000′ and 4000′ on descent. Aircraft dispatched with APU bleed inoperative. Troubleshooting completed, unable to reproduce oil smell.

Airbus A330-243 hydraulic power accumulator main—check valve rotated. SDR 510021621

During scheduled inspection of High Pressure Manifold Check Valves IAW EASA AD 2015-0009, signs of rotation found on the Yellow and Blue Hydraulic System check valves. P/No: CAR401. TSN: 11800 hours/3094 cycles

Airbus A330-243 Hydraulic power accumulator main—check valve rotated. SDR 510021792

During inspection of the high pressure manifold check valves IAW EASA AD 2015-0009, signs of rotation found in the Green and Yellow Hydraulic System check valves. No signs of black deposits or hydraulic fluid seepage was observed and the associated lock wires found not broken. P/No: CAR401. TSN: 12246 hours/3206 cycles

Airbus A330-243 landing gear retract/extension system—target damaged. SDR 510021703

During landing gear retraction after take-off, master caution followed by ECAM message L/G retraction fault occurred. Undercarriage retracted successfully on second attempt. Troubleshooting traced defect to the MLG Bogie Trail Proxy Sensor Target 29GA1 and 29GA2. Both target brackets found bent on RH MLG causing an increased distance between the proxy sensor and target face. P/No: PN55210518300ANDPN55210518400. TSN: 6660 hours/1702 cycles

Airbus A330-243 pneumatic distribution system—sense line cracked. SDR 510021658

Fan air valve pneumatic control pipe cracked. Cracked pipe subsequently replaced and system operation tested normal. Airbus investigation determined cracks on the Sense Line are likely to be caused by stress induced during pipe installation. Over torqued or loose pipe connections may contribute to premature material fatigue. P/No: F3613066000000. TSN: 8353 hours/2141 cycles

ATR ATR72212A landing gear retract/extension system—actuator failed. SDR 510021550

During climb, RH MLG failed to retract. Fault traced to RH MLG actuator which was leaking internally. P/No: D228980002.

ATR ATR72212A wheel—wheel cracked. SDR 510021794

During eddy current inspection per CMM 32-49-42 Rev 3, a minor crack indication was found on the mating face, on the outer edge of the tiebolt hole bore in the outer wheel half (P/No A36559-3). The length of the crack is approximately 0.133 inch. P/No: A365593. TSN: 1632 hours/1287 cycles TSO: 1632 hours/1287 cycles

BAC 146-100 trailing edge flap control system—flap system overspeed. SDR 510021805

FDR data identified a flap overspeed. Unscheduled maintenance check ‘Inspection after flap limiting speed has been exceeded’ (AMM 05-50-24 insp 1) was subsequently carried out with nil defects evident.

BAC 146-300 Windows wiring—windshield cracked and arcing. SDR 510021695

Air return due to arcing of LH A windscreen during climb. P/No: PNNP1701011SN96324H2861. TSN: 19057 hours/14780 cycles/218 months

BAC 146 Engine indicating system—unknown suspect faulty. SDR 510021768

On departure VIB no 1 at 3.3 noted. No MWS Chime or Lookup. V3 P3 procedure followed & engine shutdown. Engine digital display panel replaced with ‘S’ item.

Boeing 717-200 drag control actuator—proximity sensor faulty. SDR 510021616

On descent ‘spoiler OTBD fail’ annunciated, F/O RVDT replaced, SECU replaced to assist with further trouble shooting, functional and RTS tests passed ok. P/No: 3G4212B. TSN: 38047 hours/27187 cycles

Boeing 717-200 drag control actuator—spoiler system failed. SDR 510021556

During return to service check, newly installed spoiler electronic control unit (SECU) failed. SECO replaced. Investigation ongoing. P/No: 4074750401. TSN: 21084 hours/13184 cycles/133 months

Boeing 717-200 elevator control system—pushrod chafing. SDR 510021780 (photo above)

Elevator servo force limiter pushrod found chafing. Investigation revealed servo position arm installed upside down allowing the nut to chafe. P/No: 3938941501. TSN: 20522 hours/13003 cycles

Boeing 717-200 Fuselage structure—fuselage exceed per limits. SDR 510021761

The aircraft was in cruise approaching 37000 ft when it encountered moderate to light turbulence with an upward speed trend and slowly transitioned from climb to descent in V/S. Altitude exceeded 37000 ft by 120ft. Boeing have confirmed that no additional inspections are necessary and have stated that infrequent incidental excursions above the maximum operating altitude do not affect fatigue life.

Boeing 717-200 oxygen system—oxygen generator missing. SDR 510021774

During C check, it was discovered that the chemical oxygen generators and associated masks at the forward and aft FA stations were missing. Aircraft has been fitted with the required chemical oxygen generators and is in process of being returned to service post C check. P/No: E7402000.

Boeing 717-200 tire—brake incorrect repair. SDR 510021742

During maintenance, it was noted that when attempting to release the No. 3 brake, in fact the No. 4 was released and vice-versa. During trouble shooting this aircraft was compared with a nearby second aircraft and was found to be identical in the fact that the No. 1 system brake hoses located to the aft face of the R/H MLG shock struts were crossed, leading to incorrect operation. P/No: AS11606K0403. TSN: 14930 hours/9601 cycles

Boeing 737-33A landing gear actuator—hose split. SDR 510021568

Loss of system hydraulic pressure on approach. Aircraft stranded on runway due to no authority of NLG steering. LH downlock actuator return line found split. P/No: AE2464163E0192.

Boeing 737-7FE cabin cooling system—controller contaminated water. SDR 510021843

Right ram air door open light in flight. Testing found that modulation panels did not move to cruise position. Water found in ram air controller. P/No: 6075182. TSN: 15920 hours/10986 cycles

Boeing 737-800 air conditioning system—heat exchanger contaminated. SDR 510021508

During scheduled heat exchanger replacement, LH secondary heat exchanger an ACM found contaminated with yellow plastic. Heat exchanger and ACM replaced. P/No: 1828203. TSN: 4241 hours/2578 cycles TSO: 4241 hours/2578 cycles

Boeing 737-800 landing gear retract/extension system—microswitch contaminated. SDR 510021721

After take-off when landing gear lever selected up, landing gear remained down and locked. QRH followed and landing gear retracted normal after recycling the manual extension access door. An indication of LH window heat subsequently illuminated. Investigation found debris in the manual extension access door around the limit micro switch. Debris removed and area cleaned. Landing gear extension and retraction test carried out satisfactory. Cabin window heat system reset carried out.

Boeing 737-838 air conditioning system—cockpit odour. SDR 510021601

Soon after selection of take-off thrust, at approximately 75-80 kts, a fume smell was noted in the cockpit. The smell was described as ‘burning metal’, ‘chemical’ and ‘warm feeling’, and the crew reported it was difficult to breathe properly. The fume smell persisted for approximately two minutes before dissipating. It was noted that this was the first flight following a compressor wash (of the No. 1 engine).

Boeing 737-838 hydraulic system main—hose fitting failed. SDR 510021491

During climb, master caution ‘HYD’ illuminated with ‘LOW PRESSURE’ Eng 2 Hyd Pump System B. End fitting of the pressure line was found to have failed. New hose fitted and aircraft tested serviceable. P/No: 1550121221.

Boeing 737-838 waste disposal system—drain hole blocked. SDR 510021707

Rear flight attendants smelt sulphur during cruise, on approach and landing. Investigation revealed aft door water drains completely blocked.

Boeing 737-8BK brake anti-skid section—brake failed. SDR 510021509

Flight crew reported aircraft difficult to taxi. Aircraft brake No. 3 failed. Brake replaced. Investigation ongoing. P/No: 26123121. TSN: 10550 hours/5057 cycles

Boeing 737-8FE aileron control system—aileron seized. SDR 510021504

Ailerons binding in landing configuration with flaps extended. Investigation ongoing.

Boeing 737-8FE aileron control system—aileron system stiff. SDR 510021858

Flight crew reported aileron controls stiff to operate. Fault evaluation carried out with rig pins installed (pins installed freely), control wheel movement free and normal.

Boeing 737-8FE air conditioning system—aircraft interior odour. SDR 510021728

Flight crew reported oil smell for less than 20 seconds during engineNo. 1 start and just after take-off again for 10 to 15 seconds before disappearing. Normal operation continued and flight concluded with no further occurrences. Troubleshooting carried out and nil defects or obstruction noted in the APU inlet IAW FIM 49-55 Task 802. Packs operated satisfactory as per AMM 21-00-00-800-803. Engines 1 and 2 ground run test carried out with engines used as bleed source and nil odours noted.

Boeing 737-8FE air conditioning system—cabin odour. SDR 510021766

Flight crew reported acrid chemical smell fumes on the flight deck at about 200 ft shortly after rotation. Fumes dissipated gradually by 10,000 ft. Troubleshooting attributed smell to anti-seize used during overnight boroscope inspection of the engineNo. 1 HP compressor.

Boeing 737-8FE air conditioning system—cabin odour. SDR 510021827

Crew reported oil smell after starting engine no 2. Smell dissipated with packs on.

Boeing 737-8FE air conditioning system—cabin odour. SDR 510021850

Flight crew reported oil smell in the flight deck on descent at thrust idle. Cabin crew could not confirm any odours. LH Pack run hot on APU for 10 min with nil smells. LH Engine run at idle for 10 minutes with pack on hot as per FIM Task and switching selected. Nil smells confirmed. Consider odour non-oil but due to new parts fitted during heavy maintenance check recently completed. Nil re-occurrences.

Boeing 737-8FE airfoil anti-ice/de-ice system—wiring low resistance. SDR 510021725

Prior to take off, flight crew reported ANTI-ICE RAIN ENG 1 & WING CONT indication as well as associated circuit breaker tripped. Troubleshooting confirmed intermittent resistance under 3 ohm on Engine No 2 wiring harness MW0311.Harness replaced. P/No: 3250299080. TSN: 17914 hours/10897 cycles

Boeing 737-8FE air intake anti-ice/de-ice system—cannon plug disconnected. SDR 510021628

Flight crew reported cowl valve open light illuminated amber with the Anti-ice switched off. FIM 30-21 Task 804 confirmed Cowl TAI valve cannon plug disconnected. Cannon plug connection restored and operational test carried out satisfactory.

Boeing 737-8FE alternator-generator drive system—GCU intermittent. SDR 510021665

Flight crew reported DRIVE light illuminated in flight. GCUNo. 2 replaced as preventative action. IDG load test carried out normal. P/No: 762185H. TSN: 38468 hours/22135 cycles

Boeing 737-8FE APU bleed air system—APU faulty. SDR 510021812

Flight crew reported APU bleed air cycling. Investigation continuing. P/No: 38007021. TSN: 5758 hours/8798 cycles

Boeing 737-8FE APU engine fuel and control—start switch failed. SDR 510021846

APU failed to shut down when APU switch selected to off. Troubleshooting traced defect to the APU start switch which was replaced. P/No: 111AT25. TSN: 88 hours/52 cycles

Boeing 737-8FE APU oil system—APU false indication. SDR 510021778

Crew report APU ‘Maint’ Blue Light on. APU low oil quantity showing as the fault. APU shutdown and oil level checked IAW AMM 12-13-31. Oil level found to be full on sight glass. APU restarted and ‘maint’ light extinguished now. No re-occurrences to date. Investigation ongoing. P/No: 38007021. TSN: 2103 hours/2082 cycles

Boeing 737-8FE APU oil system—oil filter low pressure. SDR 510021854

Engineering reported APU oil lube filter differential pressure indicator activated. Filter service, APU run and leak check carried out. P/No: 38809381.

Boeing 737-8FE APU oil system—switch failed. SDR 510021672

Engineering reported APU auto shutdown on ground. Troubleshooting traced failure to the APU Low Oil Pressure Switch. Switch replaced and tested satisfactory. P/No: 38762552.

Boeing 737-8FE APU system—APU fault message. SDR 510021847

During APU start ‘FAULT’ illuminated. Subsequent APU start carried out satisfactory. P/No: 38007021. TSN: 7769 hours/11298 cycles

Boeing 737-8FE APU system—APU intermittent. SDR 510021671

The APU would not start on first attempt and the fault light illuminated. Second start attempt ok and APU then functioned normally. P/No: 38007021. TSN: 7657 hours/11145 cycles

Boeing 737-8FE APU system—APU low pressure. SDR 510021784

On APU power up, on bleed air selection, no duct pressure available. No circuit breakers tripped. Investigation continuing. P/No: 38007021. TSN: 7177 hours/10653 cycles

Boeing 737-8FE APU system—control valve failed. SDR 510021729

Flight Crew reported, APU Fault light on. BITE test confirmed fault code 49-522-86 for the Surge Control Valve fault. Surge Control Valve subsequently replaced and tested satisfactory. P/No: 32912382. TSN: 3659 hours/5712 cycles

Boeing 737-8FE Brake anti-skid section—brake breaking up. SDR 510021724

Flight crew reported noticeable vibration and excessive thrust required to taxi after landing. Inspection at the gate confirmed brake No. 3 partially disintegrated. Associated brake lining failed causing damage to the wheel. Brake and wheel replaced. P/No: 26123121. TSN: 10246 hours/6185 cycles

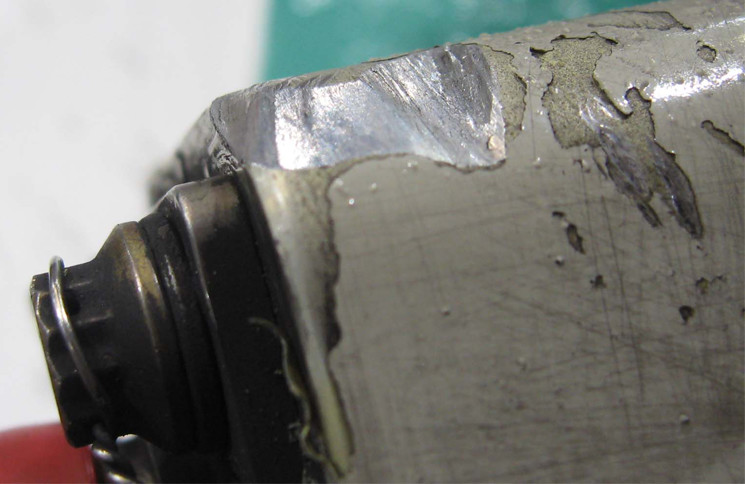

Boeing 737-8FE brake—brake caliper damaged. SDR 510021594 (photo above)

During visual inspection of the brake piston housing, damage was noticed on the lower side of the inlet boss area, with a depth of 0.071″ which is outside CMM repair limits. P/No: 26125501.

Boeing 737-8FE cabin cooling system—aircycle machine warning message. SDR 510021844

PACK light (LH) came on with recall. Cleared with master caution. MEL 21-32 applied for the associated pack temperature control system inoperative.

Boeing 737-8FE cabin cooling system—TC valve failed. SDR 510021476

RH pack light illuminated on recall after engine start. Aircraft returned to bay and MEL 21-32 applied. On climb RH Pack light illuminated again, QRH followed and flight concluded without further issue. Troubleshooting revealed TCV faulty. TCV replaced and operational tests carried out satisfactorily. P/No: 3989083. TSN: 8010 hours/4708 cycles

Boeing 737-8FE cabin temperature controller—control valve intermittent. SDR 510021688

Flight crew reported master caution RH pack light illuminated on recall and extinguishes after reset. Investigation ongoing. P/No: 3989084. TSN: 3125 hours/1158 cycles

Boeing 737-8FE cabin temperature controller—control valve worn and damaged. SDR 510021618

Aircraft returned to gate due to RH pack light illuminated on recall. Indication cleared after system reset and operational test carried out satisfactory. System health monitoring prompted preventative replacement of the Temperature Control Valve SN: 13776. Unit sent to repair and shop report subsequently revealed valve failed due to internal worn bearings. P/No: 3989083. TSN: 14641 hours/9065 cycles.

Boeing 737-8FE cabin temperature control system—air conditioning code error. SDR 510021815

Crew reported L pack light illuminates on M/C recall, reset M/C light extinguishers (left pack). Bite procedure of controller found nil faults, reset c/out, unable to reproduce fault.

Boeing 737-8FE cabin temperature control system—valve intermittent. SDR 510021557

‘Zone Temp’ light illuminated on taxi out. Fault cleared and aircraft tested serviceable, no fault found. As a prevention, trim air valve replaced. P/No: 32024441.

Boeing 737-8FE dependent position determining system—antenna failed. SDR 510021838

TCAS fail alert on climb, lower ATC antenna replaced and tested OK. P/No: DM1601354001. TSN: 10393 hours/3720 cycles

Boeing 737-8FE Doppler system—transceiver false indication. SDR 510021667

Flight crew reported weather radar fail indication at 3000 ft on approach. Operational test carried out with nil faults evident. Weather Radar operated several times and fail indication appeared briefly. Weather radar transceiver replaced and tested satisfactory. P/No: 8221710002. TSN: 9075 hours/3743 cycles

Boeing 737-8FE engine controls—control mechanism low resistance. SDR 510021781

Closing thrust levers on landing, slight resistance felt just prior to close position.

Boeing 737-8FE engine indicating system—sensor failed. SDR 510021580

RH vibration indication in blank. N2 sensor found faulty. P/No: 3218KGB01. TSN: 9575 hours/5906 cycles.

Boeing 737-8FE flight management computing software system—FMC intermittent. SDR 510021541

Flight crew reported dual FMC failure in flight. Troubleshooting could not replicate fault. P/No: 1762000101. TSN: 11966 hours/4663 cycles

Boeing 737-8FE fuselage structure—skin cracked. SDR 510021631

During NDT inspection carried out as per SB 737-53-1294 and AD 2013-19-04 in heavy maintenance, fuselage skin was found cracked at STA 540 requiring repair as per SB instructions.

Boeing 737-8FE galley station equipment system—galley odour. SDR 510021678

Cabin crew reported possible electrical smell in the AFT Galley. Smell was reported intermittent and dissipated after several minutes. Cabin crew advised smell possibly emanated from the door area heating system. Heater outlet grills cleaned and tested with nil findings.

Boeing 737-8FE HF communication system—HF system inoperative. SDR 510021853

Flight crew reported dual HF inoperative in flight.

Boeing 737-8FE Independent position determining system—TCAS failed. SDR 510021845

TCAS failed in flight, computer replaced and tested serviceable. P/No: 8222911001. TSN: 3709 hours/1270 cycles.

Boeing 737-8FE independent position determining system—TCAS incorrect fit. SDR 510021832

After take-off flight crew were requested to conduct an air return due to incorrect TCAS PN fitted to the aircraft before departure. Incorrect PN removed and correct PN fitted and tested serviceable. P/No: 8221293003. TSN: 11264 hours/3723 cycles

Boeing 737-8FE landing and taxi aids—receiver faulty. SDR 510021783

Flight crew reported GPWS inoperative. Fault confirmed as an external fault due to MMR no 2 failure. P/No: 8221821330. TSN: 11042 hours/4026 cycles

Boeing 737-8FE leading edge slat control system—proximity sensor failed. SDR 510021830

On approach when selecting Flap 15, flight crew reported leading edge flap transit illuminated. Go around was conducted and flight concluded with no issues. Troubleshooting traced defect to the LE Slat Proximity SensorNo. 7. Sensor replaced and tested satisfactory. Aircraft released to service. P/No: 189929. TSN: 37886 hours/22154 cycles

Boeing 737-8FE navigation system—EGPWS intermittent. SDR 510021677

Flight crew reported GPWS Inop light during cruise. Troubleshooting carried out satisfactory. Investigation ongoing.

Boeing 737-8FE pitot/static anti-ice system—pitot head failed. SDR 510021813

Right elevator pitot head illuminated. Defect confirmed, pitot head replaced. P/No: 0851HT1. TSN: 27449 hours/9396 cycles

Boeing 737-8FE pitot/static anti-ice system—pitot heating failed. SDR 510021483

TAT Probe light illuminated in flight. TAT probe not heating. TAT probe replaced and tested satisfactorily. P/No: 102AH2AG. TSN: 3662 hours/1538 cycles

Boeing 737-8FE pitot/static anti-ice system—pitot system failed. SDR 510021506

LH Elevator pitot probe heating. Probe replaced. P/No: 0851HT1. TSN: 14380 hours/8654 cycles

Boeing 737-8FE pitot/static anti-ice system—sensor open circuit. SDR 510021811

Temp probe annunciator light illuminated with master caution anti ice. TAT probe heater element found open circuit. P/No: 102AH2AG. TSN: 3322 hours/1271 cycles

Boeing 737-8FE Pneumatic distribution system—air conditioning odour. SDR 510021856

Flight crew reported oil smell on take-off and initial climb mainly on flight deck and FWD cabin, smell dissipated during cruise and descent. Suspect LH engine bleed as the probable cause.

Boeing 737-8FE pneumatic distribution system—sensor failed. SDR 510021763

During system health monitoring pressure split duct was reported in excess of 15 psi. Bleed air regulator and pre-cooler control sensor failed during troubleshooting. Sensor and Regulator replaced and tested satisfactory. P/No: 1269643. TSN: 17772 hours/11028 cycles

Boeing 737-8FE pneumatic distribution system—sensor suspect faulty. SDR 510021791

Low right hand duct pressure (5psi) measured in climb. Sensor assembly—bleed air over temp and pre-cooler control valve sensor replaced. P/No: 1296943. TSN: 3728 hours/1595 cycles

Boeing 737-8FE pressure control system—indicator failed. SDR 510021810

Cabin alt indicator indicates below 0′ on ground. Differential pressure indicator replaced. P/No: AW2835AB06. TSN: 6119 hours/3718 cycles

Boeing 737-8FE stabiliser control system—actuator failed. SDR 510021732

Pilot reported after take-off, electric trim on the control wheel switches were inoperative. C/O Stab trim motor logic reset. After reset stab trim worked normally. Carried out positive action by replacing stab trim actuator. All manual tests and autopilot tests passed. P/No: 6355C000101. TSN: 11996 hours/7329 cycles

Boeing 737-8FE trailing edge flap control system—seal missing. SDR 510021779

RH inboard flap lower bulb seal was reported missing. Inspection confirmed defect and new seal was fitted. P/No: 1060754275.

Boeing 737-8FE windshield rain/ice removal—window overheated. SDR 510021782

Left side window overheat light illuminated. Power breaker found tripped. Breaker reset and window heat applied for 15 minutes with no further issues.

Boeing 737-8FE wing miscellaneous structure—panel corroded. SDR 510021474

On walk around, flight crew reported pain ‘lifted’ from the outboard left wing lower surface. Inspection carried out confirmed corrosion LVL 2 in the LH lower wing skin outer panel. Damage located at WBL 635, at the rear spar attachment. Damage measures 1.4 inches x 0.6 inches & depth is 0.050 inches and exceeds SRM 57-20-01-1A-2 limits. Temporary repair carried out as per EO 737-57-20-030 by blending out the affected area as per SRM. HFEC inspection carried out satisfactorily.

Boeing 737-8KG APU bleed air system—bleed valve intermittent. SDR 510021582

APU bleed pressure fluctuating. APU bleed air valve replaced. P/No: 32912142. TSN: 14524 hours/8928 cycles

Boeing 747-438 fuselage structure—fuselage corroded. SDR 510021760

Level 2 corrosion on fuselage.

Boeing 747-438 hydraulic system main—housing leaking. SDR 510021641

Large hydraulic leak noted from L/H wing adjacent to No. 2 spoiler. Defect traced to No. 2 spoiler control package with 3″ crack in filter housing. P/No: 33205505.

Boeing 757-236 pitot/static system–pitot heating disconnected. SDR 510021726

During T/OFF-Climb, multiple failures, auto-throttle disconnected at 300 ft, Unable to re-engage. At approximately 5000 ft probe heat failures—all ASI, TAT, AOA & pitot. This was accompanied with FMC/MCP Failures-including LNAV/VNAV. On ground engineering investigated reported defects and found six pitot head CB’s tripped on P6 panel. CB’s reset and pitot probe heat system tested IAW AMM and all now satisfactory.

Boeing 777-3ZGER flight compartment windows— window cracked. SDR 510021569

Shortly after departure, forward LH window shattered. OEM current investigating fleetwide issue. P/No: 141W740043. TSN: 18510 hours/1407 cycles TSO: 18510 hours/1407 cycles

Boeing 777 cabin systems—audio jack short circuit. SDR 510021699

Burning plastic smell emanating from seat level, traced smell to USB ports. USB ports replaced.

Boeing 777 Passenger compartment lighting—lamp holder burnt. SDR 510021823

Burning smell in 4R toilet traced to burnt lamp holder. Lamp and holder replaced. P/No: BV03202N0150.

Boeing 787-8 cabin cooling system—aircycle machine unknown. SDR 510021536

Burning smell present on take-off, accompanied by vibration under floor at D3. P/No: 7010121H03. TSN: 6847 hours/1261 cycles

Boeing 787-8 central display—display unit suspect faulty. SDR 510021537

Captain’s inboard and outboad display units blanked with loss of all flight information on captains side. On shutting down aircraft engines all systems restored to normal.

Boeing 787-8 galley station equipment system— oven overheated. SDR 510021622

Galley oven 1F1L08 overheated and suspected it did not auto-shut down.

Bombardier BD7001A10 flight compartment windows—windshield arced. SDR 510021583

Vertical optical distortion line in LH windshield left of centre. Arcing observed at top of windshield.

Bombardier CL604 fuselage structure—fuselage bird strike. SDR 510021522

Suspect bird strike on departure.

Bombardier DHC8-102 brake—housing cracked. SDR 510021689 (photo above)

Utilising fluorescent penetrant inspection a 3.5 mm crack was detected in one of the brake housing cylinder bores.

Bombardier DHC8-201 flight control system—unknown. SDR 510021572

Flight controls stiff when in neutral position to commence right turns, but felt normal when conducting left turns. Investigation ongoing.

Bombardier DHC8-202 cabin cooling system—aircycle machine unserviceable. SDR 510021503

Prior to boarding cabin crew noticed cabin filling with strong smelling smoke/mist. Trace to the ACM. Investigation ongoing. P/No: 78279018.

Bombardier DHC8-202 flight compartment windows—window cracked. SDR 510021733

Co-pilot windshield cracked at FL250 with ice protection on and OAT -29C. Co-pilot windshield replaced with new item. Windshield heater terminals to be refitted. Electrical terminals reconnected IAW AMM 56-10-11 function check c/o— serviceable. P/No: 8SC0043014.

Bombardier DHC8-202 flight controls wiring—circuit breaker intermittent. SDR 510021657

Flaps observed to mot move when selected away from zero. Fault traced to intermittent flap cont. circuit. New breaker fitted, aircraft tested serviceable. P/No: MS33205.

Bombardier DHC8-202 wing control surface attach fittings—bolt not engaged. SDR 510021851

During C check it was found that a bolt replacement was required in the flap torque tube, out board of the flap motor on the left hand wing. Upon closer inspection it was discovered that the bolt was fitted to the torque tube but not engaged in the splined drive per the AMM.

Bombardier DHC8-315 aerodynamic fairing—radome damaged. SDR 510021842

During flight, a large bird was seen and felt hitting the front nose area of the fuselage. Engineering inspected the aircraft and found damage to the upper left hand side corner of the radome/bulkhead at X-7.00. Damaged metallic structure removed and repaired. Damaged composite structure repaired.

Bombardier DHC8-315 APU oil system—oil filter leaking. SDR 510021519

During pre-flight checks with APU on, bleed air selected and cabin filled with smoke. APU compressor intake shroud found displaced and APU oil filter bowl found leaking. P/No: WF326058.

Bombardier DHC8-315 emergency equipment system—life jacket faulty. SDR 510021712

Lifejacket P/N TYPE 11A, S/N 3290 was accidentally activated. It was noted that the right hand side inflated correctly but the left hand side did not.

Bombardier DHC8-315 emergency exits—emergency exit leaking. SDR 510021659

Loud air noise reported from LH type 3 emergency exit. Exit removed and re-seated no further defect evident.

Bombardier DHC8-315 flight compartment windows—window sparking. SDR 510021777

Co-pilot windshield arcing in top right corner (at element) intermittently, with windshield heat selected to ‘warm-up’.

Bombardier DHC8-315 pressure regulator valve—drain valve incorrect fit. SDR 510021563

Manifold drain valve found unseated. Re-seated and function checked ok.

Bombardier DHC8-402 cargo compartment lighting—terminal burnt. SDR 510021744

On routine Inspection of cargo area the terminals to the cargo bay lights were found severely heat affected. The insulation was found to be charred or missing. The plastic fitting on the light was also heat affected and broken. Investigation ongoing.

Bombardier DHC8-402 drag control system—lift spoiler jack failed. SDR 510021681

LH spoilers retracted normally, but indication of RH spoilers showed both inboard and outboard spoilers approximately 1/4 deployed. Inspection of spoiler rigging found cable tension outside limits.

Bombardier DHC8-402 engine oil system (airframe)—oil system leaking. SDR 510021817

No 2 engine oil leak detected. Transfer tube support retainer chafed through oil pump housing. P/No: 766859C. TSN: 11429 hours TSO: 10838 hours

Bombardier DHC8-402 Horizontal stabiliser structure—barrel nut cracked. SDR 510021600

During inspection of horizontal stabiliser attachment barrel nuts per AD CF-2015-13 and Bombardier SB A84-55-04, L/H and R/H mid-spar attach bolt barrel nuts were found cracked. P/No: DSC22810. TSN: 13853 hours/15442 cycles

Bombardier DHC8-402 pitot/static anti-ice system—pitot system unserviceable. SDR 510021638

Pitot Heat No.1 caution light illuminated. L/H air data probe was replaced, tested and leak-checked. System checked serviceable. Investigation continuing.

Bombardier DHC8 engine indicating system—plug resistance check. SDR 510021806

During line check engineers noted that ECP indicated fault codes were stored in EEC. Trim resistor values were checked and found to be incorrect (not matching engine data plate) replacement EEC plug fitted with correct trim resistor values. P/No: 312283501.

Bombardier DHC8 hydraulic system main—tube leaking. SDR 510021797

During taxi in the cabin crew reported a fume like smell in the cabin. After parking on bay the cabin crew reported the fumes were becoming irritating and a mist/haze could be seen. After shutdown and during disembarkation the fumes appeared to dissipate. P/No: BMS7185X375X020. TSN: 28025 hours TSO: 26437 hours

British Aerospace JETSTM3201 landing gear door actuator —washer faulty manufactory. SDR 510021772

BAE requires mod SB 32-JM7862R3 to be incorporated at next scheduled leg removal (overhaul) which was supplied incorporated with the overhauled leg as per the mandating of EASA AD No. 2014-0239. This AD has the background as to why the special washer is installed. The SB has been amended 3 times so far, to prevent this washer migrating without success. P/No: 13744B31. TSN: 46 hours/35 landings TSO: 46 hours/35 landings

CASA C212EE Landing gear actuator—torque link damaged. SDR 510021608

Damage found on LH MLG torque links. When wheel removed and oleo fully extended, it was apparent that the lower torque link had been incorrectly fitted. Damage repaired and torque links reinstalled in correct orientation.

CASA C212EE landing gear steering system—nose wheel steering misaligned. SDR 510021825

Nose wheel not aligned with steering tiller centred. Aircraft nose wheel 10 degrees right with Steering tiller centred. Steering cable tensions adjusted.

Cessna 750 Wing miscellaneous structure—landing gear door cracked. SDR 510021515

Eddy current inspection carried out on LH and RH lower wing landing pads IAW NDTM. Indications of cracks found in 2 panels.

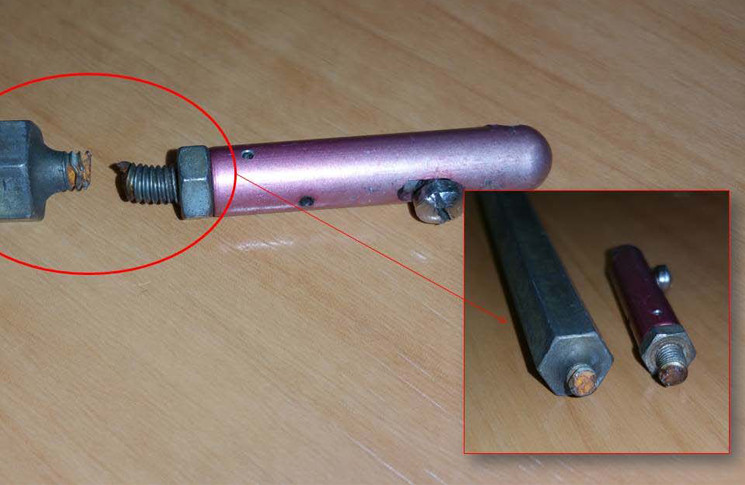

Embraer EMB-120 Indicating/recording system—connecting rod sheared. SDR 510021551 (photo above)

During phase check inspection, RVIT connecting rod found sheared at threaded point. P/No: 12063143001.

Embraer EMB-120 Trailing edge flap actuator—actuator unserviceable. SDR 510021538

Flap disagreement on approach. Both outboard flap actuators were found to be the source of the issue. P/No: 3203001007.

Embraer EMB-120 wing spar—spar cracked. SDR 510021730

Crack discovered in right hand lower forward wing spar. Crack appears to be 4-6 inches outboard of rib 17. Manufacturer confirmed that crack can be repaired in accordance with structural repair manual. P/No: Unknown. TSN: 40826 hours/38312 cycles.

Embraer ERJ-170 air distribution fan—relay suspect faulty. SDR 510021493

During taxi, strong electrical smell entered cockpit. Cabin crew and some passengers reported sore eyes and nausea. Investigation revealed faulty relay K5 in LICC. P/No: RELAYK5.

Embraer ERJ-170 service doors—service door damaged. SDR 510021762

Damage found aft of rear service door. Affected areas inspected fuselage skin & door damage blended.

Embraer ERJ-170 wing miscellaneous structure—winglet damaged. SDR 510021662

Damage on L/H winglet trailing edge due to impact with ground service equipment. P/No: 17016200403.

Embraer ERJ-190-100 air conditioning system—air conditioning smoke/fumes. SDR 510021477

Report status: Interim flight crew reported oil fumes in the cockpit on take-off and approach. Nil smell detected in cabin. FIM 21-20-00-810-803 carried out satisfactory. Nil defects found. On 15/07/2015 flight crew reported oil fumes for two seconds on take-off. Troubleshooting carried out suspected Engine No.1 bleed at fault. MEL 36-00-00A applied for the associated engine bleed system inoperative. Further troubleshooting carried out as per FIM 21-20-00-810-803 satisfactory. APU check and engine run carried out with nil smell evident. MEL removed. Monitoring is ongoing.

Embraer ERJ-190-100 aircraft fuel distribution system—pressure switch corroded. SDR 510021529

Fuel feed 1 fault caused air turn-back. Troubleshooting traced defect to engine No.1 low pressure switch. Switch found corroded. Switch replaced. P/No: 8H00251G.

Embraer ERJ-190-100 cabin temperature control system–bypass valve failed. SDR 510021496

Cabin temperature difficult to control. LH pack bypass valve found faulty. Valve replaced tested satisfactory. Investigation ongoing. P/No: 8209147.

Embraer ERJ-190-100 Fuselage internal stairs—cabin door corroded. SDR 510021530

Level 2 corrosion found on aft passenger door cut out lower beam. P/No: 17065703005. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 fuselage internal stairs—floor beam corroded. SDR 510021534

Level 2 corrosion found in aft cabin floor wet area RH floor beam. P/No: 17065669004. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 fuselage internal stairs—panel corroded. SDR 510021533

Level 2 corrosion found in aft cabin floor wet area. P/No: 17086181005. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 Fuselage internal stairs—panel corroded. SDR 510021535

Level 2 corrosion found in aft cabin wet area RH shear panel. P/No: 17091919001. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 fuselage internal stairs—skin corroded. SDR 510021532

Level 2 corrosion found in fuselage skin doubler at waste box cut out.P/No: 17066931001. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 Fuselage miscellaneous structure—door frame corroded. SDR 510021668

Inspection of the rear passenger door cut-out found corrosion on lower beam common to the aft girt bar attach fitting. P/No: 17065703005. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 Fuselage miscellaneous structure—panel corroded. SDR 510021644

Corrosion found on LH Shear Panel between Frame 87 and 88, LBL 12 and outboard (aft cabin wet area). P/No: 17065927007. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 Fuselage miscellaneous structure—panel corroded. SDR 510021645

Corrosion found on the centre shear panel between frame 87 and 88, LBL 12 to RBL 12 (aft cabin wet area). P/No: 17065928001. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 fuselage structure—crossbeam corroded. SDR 510021517

During C check, Lvl 2 corrosion found on floor crossbeam.

Embraer ERJ-190-100 fuselage structure—crossbeam corroded. SDR 510021642

During maintenance check corrosion found on Frame 17 Cross Beam between RBL 12 and RBL 40. Corrosion assessed as Level 2 in Primary Structure Element IAW SRM Ref 53-10-027. Permanent repair carried out IAW Embraer ETD2015-190-071777. P/No: 17021769403. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 fuselage structure—floor corroded. SDR 510021646

Corrosion found on seat track at RBL 10, between frame 15 and frame 17 (6 locations), two locations found to be outside of SRM limits. P/No: 17003263001. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 fuselage structure—floor panel corroded. SDR 510021643

Corrosion found on right hand shear panel between frame 87 and 88, RBL 12 and outboard. Corrosion assessed as Level 2 in primary structure element IAW SRM Ref 53-23-005. P/No: 17091919001. TSN: 16316 hours/10737 cycles.

Embraer ERJ-190-100 fuselage structure—panel corroded. SDR 510021518

During C check, AFT cabin ‘wet area’ found with level 2 corrosion on the centre shear panel. Error in SRM reference please read as 53-23-05. P/No: 17065928001. TSN: 10746 hours/7693 cycles

Embraer ERJ-190-100 fuselage structure—seat track corroded. SDR 510021531

Level 2 corrosion found on seat track common to galley mounting point. P/No: 17003263001. TSN: 10746 hours/7693 cycles.

Embraer ERJ-190-100 fuselage structure–splice corroded. SDR 510021516

Corrosion found in floor splice forward ‘wet’ area. Assessed as level 2 corrosion. P/No: 17012114001. TSN: 10746 hours/7693 cycles

Fokker F27MK50 air conditioning system—cabin odour. SDR 510021540

Aircraft had strong burning smell on climb. Aircraft performed air turn back and landed. Investigation carried out—both engine oils checked, ACM oils inspected, ACM turbines inspected and rotated, engine ground run for approx. 30 minutes, packs operated at high and low temperatures, all systems operated and functional checks c/o. Bleeds operated on and off—no smell apparent in cockpit or cabin. Aircraft has since flown without further incident.

Fokker F27MK50 engine controls—solenoid failed. SDR 510021552

During scheduled maintenance, No. 1 engine failed AFISS operational check at step 5. AFISS solenoid found unserviceable. Investigation ongoing.

Fokker F27MK50 engine controls wiring—wiring damaged. SDR 510021697

During the course of auxiliary power unit (APU) fault investigation, engineering staff identified significant arcing damage to APU Generator Wires GZG0030-B3 and GZG0031-B3, and the right hand nacelle frame (FRA) 5752, between Stringers T1 and S2.

Fokker F27MK50 flight compartment windows—window damaged. SDR 510021759

Flight crew reported that the left hand sliding cockpit window, inner pane had cracked. Engineering staff removed the sliding window from the aircraft, and the pane from the window surround in preparation for window replacement, subsequently identifying corrosion on the window surround.

Fokker F28 MK0100 AC inverter—circuit breaker faulty. SDR 510021480

Prior to departure, flight crew reported failure of multiple aircraft avionics systems. Circuit breaker CB0542A replaced, system declared serviceable.

Fokker F28 MK0100 air conditioning system—air conditioning failed. SDR 510021553

Air-conditioning pack shut down following suspected failure. ACM failed in vicinity oil dip-stick, with portions of the units casing found adrift. Damage to the ACM exhaust turbine. TBV was also replaced.

Fokker F28 MK0100 air conditioning system—air conditioning failed. SDR 510021574

Aircraft suffered pack failure in cruise. Passenger oxygen deployed. Investigation ongoing.

Fokker F28 MK0100 air conditioning system—air conditioning failed. SDR 510021743

During flight, noise and vibration was heard from under the captain’s side cockpit floor, which subsided after switching the No. 1 air-conditioning pack off. No. 1 High Pressure (HP) Valve was not closing at high power settings. The left hand flow control valve was found to be stuck in normal mode. Further troubleshooting then resulted in the replacement of the No. 1 air cycle machine (ACM) and pack, and turbine bypass valve. During ACM replacement, engineering staff identified a test pressure tube damaged downstream near a forward fitting. The tube was resultantly re-flared, with leak checks carried out without fault. The left hand HP bleed sensing switch was then replaced and adjusted and the right hand was adjusted, with further operational checks carried out without fault.

Fokker F28 MK0100 air intake anti-ice/de-ice system—relief valve unserviceable. SDR 510021818

Flight Crew encountered a No. 1 engine anti-ice fault, which they were unable to reset. Investigation by engineering staff identified a seized/damaged anti-ice pressure relief and shut-off valve (PRSOV) Cannon plug and receptacle, with the plug and valve resultantly replaced. chafed wiring was also identified adjacent to the plug, with no wire core damage noted, and the insulation repaired as required.

Fokker F28 MK0100 APU cowlings/containment—heat shield corroded. SDR 510021687

Corrosion identified around APU heat shield. Corrosion removed and blended as required.

Fokker F28 MK0100 cabin cooling system—air cycle machine failed torque check. SDR 510021615

Aircraft suffered pack failure in cruise. Passenger oxygen deployed. Pack replaced, aircraft returned to service. P/No: 22058205. TSN: 3895 hours TSO: 3895 hours.

Fokker F28 MK0100 crew station equipment system—FCC failed. SDR 510021597

Flight crew of unable to engage Auto-Pilot No. 2, although Land 2 remained engaged. The flight crew then encountered a rudder reversal, with 1/3 deflection of both rudder pedals, and an uncontrolled movement of the aircraft, due to an uncontrolled rudder movement. Subsequent investigation by engineering staff identified that flight control computer (FCC) No. 2 failed to test, resulting in the replacement of the Unit. Additional operational checks were then carried out without fault, and the system was declared serviceable.

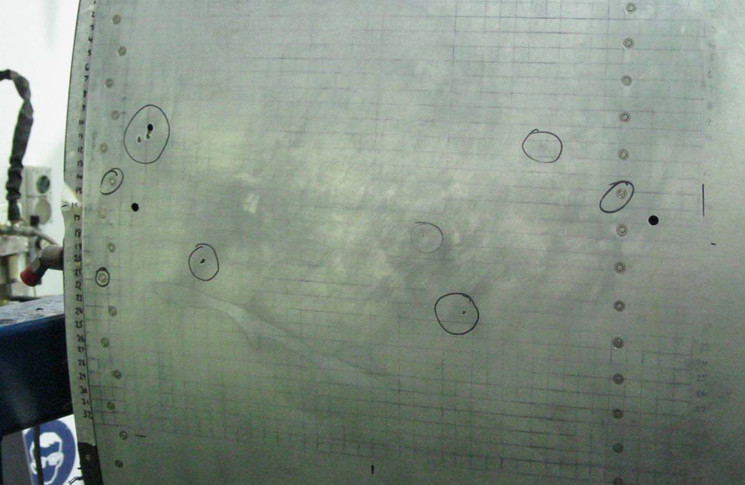

Fokker F28 MK0100 engine cowling system—cowling corroded. SDR 510021604 (photos above)

Severe ‘worm hole-type’ corrosion evident in aft cowl skin. Damaged spigot mounting holes, migrating rivets. P/No: 1159P4144041.

Fokker F28 MK0100 flight compartment lighting—light bulb incorrect dimensions. SDR 510021836

Engineering staff reported that they had identified jammed cockpit overhead panel switches, with investigation identifying the installed Lamps to have incorrect dimensions. Further investigation by engineering staff and quality and safety personnel has identified that the lamps have been manufactured with larger dimensions; particularly the dimension of the lamp side flange contactor, and between the side flange contactor and the base contactor. P/No: GE6839.

Fokker F28 MK0100 flight compartment windows—windshield cracked. SDR 510021829

During flight, the right hand side cockpit windshield cracked. Engineering staff replaced the effected windshield, with the aircraft then declared serviceable.

Fokker F28 MK0100 fuselage equipment attach fittings—skin damaged. SDR 510021686

GPU moved while still connected, damage to ground power receptacle and NLG bay doors.

Fokker F28 MK0100 hydraulic pump main—pump unserviceable. SDR 510021586

During pre-flight inspection skydrol hydraulic fluid leak was detected from the No. 1 engine nacelles. Subsequent inspection, identified that the leak was emanating from the No. 2 Pump which was replaced. Investigation ongoing.

Fokker F28 MK0100 landing gear actuator—actuator leaking. SDR 510021584

Engineering staff identified skydrol hydraulic fluid leaking from the right hand main landing gear (MLG) downlock actuator, with what appeared to be a migrated O-Ring. Downlock actuator replaced, system declared serviceable.

Fokker F28 MK0100 landing gear door retract section—actuator leaking. SDR 510021602

Evidence of hydraulic RH main landing gear area. Hydraulic oil found to be coming from RH MLG retract actuator UP Line at actuator. Union & O-ring replaced.

Fokker F28 MK0100 main landing gear attach section—bracket corroded. SDR 510021591

During scheduled heavy maintenance, engineering staff identified corrosion on the left and right hand wing, main landing gear (MLG) Bracket, MLG side stay bracket, and rear spar fittings. Engineering staff have removed the corrosion, and spot-faced the areas as required.

Fokker F28 MK0100 wing miscellaneous structure—wing strap corroded. SDR 510021592

During scheduled heavy maintenance, engineering staff identified corrosion under the right hand main landing gear (MLG) outboard door hinge, on the lower wing surface strap. Engineering staff have removed the corrosion, and blended the areas as required, with the removed material measured, and repair advice sought from Fokker Services.

Fokker F28 MK0100 Wing spar—spar corroded. SDR 510021588

During scheduled heavy maintenance, engineering staff identified corrosion on the front spar of the left and right hand wing, between wing stations (WSTA) 9910 and 13550.

Fokker F28 MK0100 wing spar—spar corroded. SDR 510021589

While carrying out Service Bulletin (SB) SBF100-57-049 during scheduled heavy maintenance, engineering staff identified corrosion on the left and right hand wing rear spar. Engineering staff have removed the corrosion, and blended the areas as required, with the removed material measured, and repair advice sought from Fokker Services.

Fokker F28 MK0100 wing spar—spar cracked. SDR 510021590

During scheduled heavy maintenance, engineering staff identified a crack on the right hand wing auxiliary front spar lower girder, at wing station (WSTA) 8200. Damaged portion of spar replaced in accordance with instructions from Fokker.

Fokker F28 MK070 auto flight system—autopilot suspect faulty. SDR 510021828

During flight, with Auto-Pilot (AP) no1 engaged, the aircraft performed an uncommanded descent. Later whilst performing a descent during the same flight, the flight crew encountered an ‘out of trim—nose up’, multifunction display unit (MFDU) warning. Investigation ongoing.

Fokker F28 MK070 autopilot computer—display unit suspect faulty. SDR 510021596

During descent with the auto-pilot engaged the flight crew encountered an uncontrolled pitch down. The flight mode panel was replaced, and the system was declared serviceable.

Fokker F28 MK070 exterior lighting—landing light SUP. SDR 510021613

Landing Light, PN: 45-0234-3 SN: 0583 on PO M77986 received however upon receipt the unit could not be added to the maintenance control program as a Landing Light, PN: 45-0234-3 SN: 0583, with identical part information was already installed other aircraft. P/No: 4502343.

Fokker F28 MK070 fire protection system—actuator unserviceable. SDR 510021647

while carrying out an emergency shut-down system operational check the right hand fuel fire shut-off valve (FFSOV) failed to travel from the open to closed position in three seconds (took approximately eight seconds to actuate). FFSOV actuator replaced.

Fokker F28 MK070 Flight control system—flight control unit suspect faulty. SDR 510021696

During descent the flight crew encountered an uncontrolled pitch down of the Aircraft for approximately one second with the Autopilot engaged, with a No Autoland message displaying. Troubleshooting by engineering staff identified automatic flight control and augmentation system (AFCAS) faults. Investigation continuing.

Fokker F28 MK070 flight control system—flight control unit suspect faulty. SDR 510021713

During descent, the flight crew encountered an uncontrolled pitch down of the Aircraft for approximately one second with the Autopilot engaged, with a No Autoland message displaying. Investigation ongoing.

Fokker F28 MK070 flight control system—flight control unit suspect faulty. SDR 510021715

During flight with Autopilot engaged, the flight crew encountered an uncontrolled pitch down and then up of the aircraft. Troubleshooting by engineering staff identified automatic flight control and augmentation system (AFCAS) maintenance panel (AMP) diagnostic code No. 121840, elevator servo jammed, with the subsequent elevator servo, AFCAS Test carried out without fault.

Fokker F28 MK070 Ice and rain protection wiring—wire damaged. SDR 510021479

During scheduled anti-ice system wiring modifications, discolouration and melting of a system wire was discovered. Inspection of the surrounding area identified no further damage. Damaged wire replaced, investigation determined that the damage was probably caused by high resistance at the wire/splice interface.

IAI 1124 DC generation system—bearing collapsed. SDR 510021723

Airframe vibration felt through airframe. Vibration ceased when RH 3 engine shut down. Engineering confirmed that the RH DC Generator was the source of the engine vibration. This component was replaced and the aircraft returned to service with nil further related defects. The strip report for the DC Generator notes that the ADE (armature drive end) bearing cage had collapsed allowing the ball bearings to move around erratically. P/No: 03601018.

IAI 1124 Power lever—cable suspect faulty. SDR 510021757

LH power lever was extremely difficult to move during flight, as if the friction was too tight. As the aircraft passed through 11,000 ft the power lever had started to move more freely and by 5000 ft normal full and free movement was restored. Investigation ongoing. P/No: 5536281.

Lear Jet 36A DC generation system—generator unserviceable. SDR 510021701

During flight it was noted a minor generator rumble was evident followed by a RH generator failure indication. Investigation found RH generator physically binding internally when rotated causing subsequent failure of RH voltage regulator. P/No: 66082019. TSO: 1148 hours/404 cycles/404 landings/36 months.

Lear Jet 45 detection system—fire detector failed. SDR 510021700

During pre-flight inspection it was noted the RH engine fire detection system failed to test. Fault was isolated to open circuit RH engine hot section fire detection loop. After further access it was noted the RH hot section fire detect loop was broken at the rear of the upper engine deck disconnect. Detection element was removed and replaced, aircraft restored and operational testing carried out with nil further defects detected. P/No: 74412135. TSN: 4119 hours/3159 cycles/3159 landings/117 months.

Saab SF340A Landing gear retract/extension system—controller unserviceable. SDR 510021691

On departure, the crew selected gear up and the disagreement light in the landing gear control handle failed to illuminate. It did work during the subsequent extension of the gear. Engineering investigation confirmed the fault was in the landing gear controller PN: D494-12-001. The controller has been replaced and the aircraft has been returned to service. P/No: D49412001. TSO: 198 hours/146 cycles.

Saab SF340B DC generation system—PDU faulty. SDR 510021702

LH power distribution unit (PDU) faulty. PDU failed due to internal FOD contamination. PDU replaced. P/No: A2042C. TSN: 49539 hours/51597 cycles.

Saab SF340B EICAS—circuit breaker blanked off. SDR 510021545

After rotate, F/O EFIS screen went blank. On taxi, nose wheel steering became inoperable. Fault traced to R/H Avionics switch intermittent in operation, sometimes internal short to GND causing CB to pop. Switch assembly replaced.

Saab SF340B Landing gear retract/extension system—landing gear unserviceable. SDR 510021640

After landing gear was retracted, the landing gear disagreement light in the handle was not illuminated. Engineering staff confirmed the defect and replaced the landing gear control panel. P/No: D49412001. TSO: 8661 hours/9323 cycles

Saab SF340B Pneumatic system—duct disbonded. SDR 510021706

LH bleed duct rubber gooseneck ducting found disbanded. Ducting replaced. P/No: 9303688100.