Single-engine aircraft are often operated privately under IFR, but traditionally, charter and air transport under IFR have been limited to twins. Nick Stobie looks at the exception to this rule – the prescribed single-engine aeroplane (PSEA) – and what it means for operators and their crews.

In 2019 I wrote my first article for Flight Safety Australia, ‘Your one and only: mitigating the risk of engine failure in singles’. It was a dive into some key tenets of risk management for single-engine aircraft, taking elements I’d learnt from my career in several organisations that operate Cessna Grand Caravans and Pilatus PC12s.

These aircraft were operated under the approved single-engine turbine-powered aeroplane (ASETPA, but since 2 December 2022 known as prescribed single-engined aeroplanes or PSEA) provisions of the regulations which granted operators the ability to fly single-engine aircraft under IFR and at night under VFR while carrying passengers on charter. This type of work has traditionally been performed by twin-engine aircraft like Piper Chieftains, Cessna 400 series and Beechcraft King Airs, but increasingly single-engine IFR air transport (previously charter or RPT) is now being fulfilled by Cessna Grand Caravans and Pilatus PC12s which appear to be becoming a mainstay of the Australian aviation industry.

With the regulatory transition to Parts 119, 135 and potentially subpart 121.Z of the CASRs currently underway for charter (Australian air transport) category operators, the ASETPA standard has been replaced by the prescribed single-engine aeroplane (PSEA) terminology under Part 135 of the CASR.

Over the past year, I’ve been lucky enough to lead Kirkhope Aviation, a Part 135 Australian air transport – smaller aeroplane operator – based at Moorabbin, through the transition to Part 135 regulations and PSEA operations for our Cessna Grand Caravan EX. We were one of the first operators to adopt PSEA operations under the new flight operations regulations, having only added the Caravan type to our operations in late 2021.

With our transition now completed, I’d like to share a bit more about what PSEA is and what that looks like for a small organisation like ours.

The backstory

In the 1980s, passenger-carrying IFR charter operations were limited to twin-engine aircraft, with the prevailing logic being that only twins offered an adequate level of safety for non-visual operations.

Unless managed well, even en route failures can result in off-field landings or controlled flight into terrain

However, an engine failure after take-off or en route remains a real threat for multi-engine aeroplanes. Unless managed well, even en route failures can result in off-field landings or controlled flight into terrain. In June 2010 a Piper PA31P-350 Mojave suffered an engine failure passing 7,500 feet while departing Bankstown Airport. The aircraft collided with terrain 3 nm short of the airport.

Two factors began to challenge the exclusive use of twins for IFR charter – the development of reliable single-engine turbine aircraft and the cost of operating twin-engine aeroplanes.

With the improvement in reliability, Pratt & Whitney now claims an in-flight shutdown rate for the PT6 turboprop approaching one failure per million flight hours – single-engine turbines were becoming safer. Other design mitigations of trend monitoring, secondary engine controls and backup instrument power were further reducing the risks of an engine failure. Although still not low enough to ignore the consequences of an engine failure, it gave operators reasonable confidence they were unlikely to encounter forced landings on any regular basis.

CASA began approving some operators to fly certain single-engine types under IFR for passenger-carrying charter, in IMC or at night, outside of glide range of a suitable forced landing area, under what became known as ASETPA and now redefined as PSEA.

What is the PSEA standard?

PSEA is defined in CASR 135.240, which refers to the Part 135 Manual of Standards (MOS). Chapter 8 of the 135 MOS lays out which aeroplanes, and how, where and what is necessary to operate them as PSEA.

PSEA itself refers to the aeroplane, with the Cessna 208 Caravan family, the Pilatus PC12 and the Socata/Daher TBM family being the only aircraft in Australia approved to operate under PSEA at the time of writing.

PSEA aeroplanes are about mitigating the risk of the inherent single point of failure of a single-engine design. This is done by using power plants that have very low failure rates, adding other design features that further reduce the likelihood of an engine failure (trend monitoring and secondary engine controls) and increasing the survivability (backup instrument power) if one was to occur. Hence, the aeroplane by design mitigates against engine failure and additionally the operation needs to do the same by prevention (maintenance and trend monitoring), training (across all phases of flight) and preparation (suitable routes and suitable forced landing areas) for engine failures.

Design

For PSEA, the aeroplane engine is designed not to fail, to pre-empt a failure by monitoring trends and be more survivable in the event of an engine failure.

PSEA aircraft are required to be equipped with additional equipment, including:

- a radio altimeter for forced landings without accurate local QNH or survey height data

- a weather radar to reduce the likelihood of penetrating hazardous weather

- 2 independent instrument power sources (normally a second generator or alternator) to provide for use in the event of an engine failure

- specific seat crashworthiness requirements, with seats required to meet the more stringent requirements of FAR 23.562.

The aeroplane by design mitigates against engine failure

Prevention

At an organisational level, PSEA operators are required to implement specific programs for managing the maintenance of their aircraft. This starts with a system of maintenance specific to ASETPA/PSEA requirements, including engine condition trend monitoring which tracks the performance of the engine to identify deviation of parameters prior to a failure manifesting. A reliability program that tracks recurrence of defects or unscheduled maintenance in the fleet is also required.

Training – practice makes perfect

Although now required for all operators under Parts 119 and 135 of the CASR, ASETPA previously required operators to implement a formal training and checking program under CAR 217. This essentially continues with PSEA.

Contained within this program is how the operator brings its pilots up to speed on operating their aircraft, including procedures prescribed by the 135 MOS which, for many pilots, will be new. Operators identify how they will handle an engine failure in all phases of flight, along with how and when they will train and assess their flight crews as competent.

Preparation – planning for the worst

Guarding against an engine failure is something that most single-engine aircraft pilots do automatically. Choosing an appropriate route to fly (avoiding unfavourable terrain for forced landings) and considering en route alternates happens almost intuitively in the planning process. PSEA formalises and systemises some of these strategies.

At the planning stage of a flight, Part 135 MOS 8.08 limits the time a PSEA aircraft can plan to be outside of glide range to a suitable landing area, to 15 minutes – a change from no time limitation under ASETPA for charter operators. Operators are required to define, map and document suitable landing areas on each route (or area of operation) to allow pilots to manage this, with each landing area loaded into the GPS or FMS database. In an emergency, the ‘nearest’ function on the FMS or GPS allows the pilot to immediately identify what pre-assessed areas are available for a forced landing.

In exchange for taking these steps, PSEA operators are granted several additional privileges not available to a non-PSEA operator:

- passenger-carrying or medical transport operations under IFR – CASR 135.230 (2) – and at night under VFR – CASR 135.235 (2) – noting other conditions may also need to be met

- increased permitted distance for flights over water (outside of gliding range).

For Kirkhope Aviation’s operations, a map overlay (a .KMZ file) within AvPlan allows pilots to clearly visualise which routes and areas are suitable for PSEA operations.

Both AvPlan and OzRunways are developing tools that will continue to improve this process. Often altering a route only 5–10 nm off track can drastically increase the number of suitable landing areas available within gliding range.

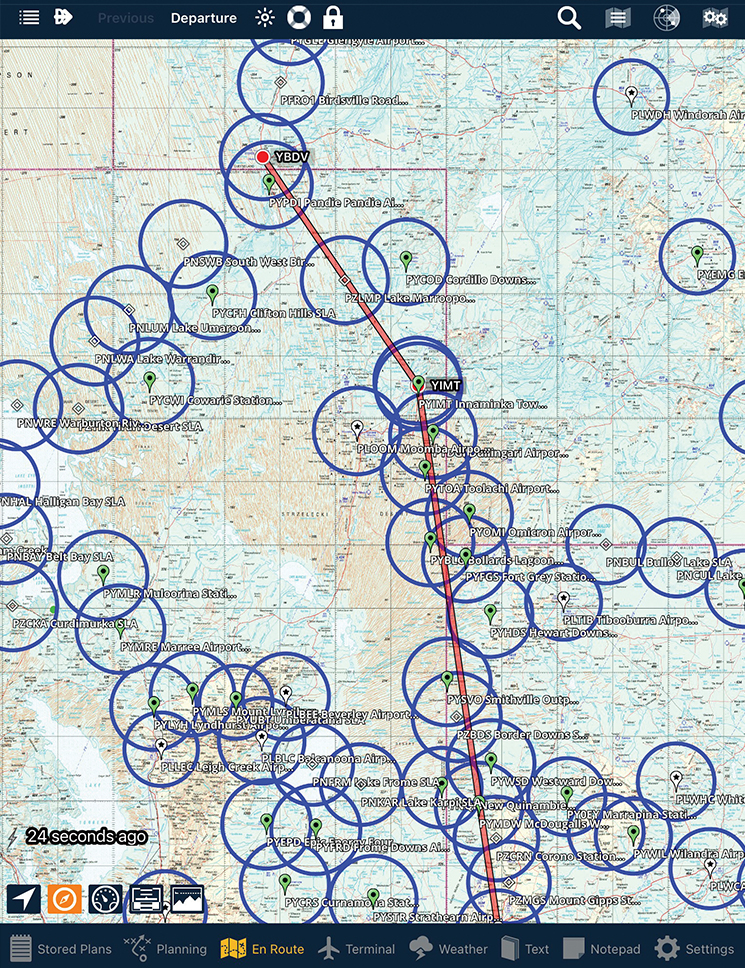

In image number 1, the blue circles denote nil-wind glide radius from cruise altitude for each suitable landing area. Differing symbols denote each type of landing area, for example, a field, a lit aerodrome and an unlit aerodrome. Even on this relatively remote route between Broken Hill, Innamincka and Birdsville, the aircraft is outside of glide range for only 2 short periods between Innamincka and Birdsville, each much shorter than the 15-minute limit recently mandated under Part 135 for passenger or medical transport (previously there was no time limit). However, limiting time outside of glide range had already been the norm for some operators.

Kirk Campbell, Chief Pilot at Seair Pacific, another ASETPA/PSEA C208 operator, explained how this came about for their operation. ‘Some of our clients have required this level of risk management for single-engine aircraft operations for sometime,’ he says. ‘Seair Pacific first started mapping safe forced-landing areas back in 2004, driven by audit requirements for servicing mines in central Queensland. For those contracts, our auditor and the mining companies required our aircraft to be within glide of a suitable landing area at all times, beyond even the current PSEA requirement.’

A shorter leap

ASETPA has traditionally been a large leap for smaller general aviation operators. While no one element of the certification was a particular challenge, the existing requirement to establish a CAR 217 training and checking program was one of the more onerous hurdles to achieving certification.

The transition to Parts 119 and 135 of CASR, which is currently underway, replaces CAR 217 and requires training and checking programs for air transport operators. PSEA requirements prescribe which additional scenarios need to be covered by the operator’s training and checking program. There is now significantly more guidance material available from CASA on this process as a result, which makes taking the leap towards PSEA more achievable in the new regulatory environment.

The remainder of the certification process is relatively straightforward; however, engaging the right people remains key. Operators starting the journey down the PSEA path may have personnel with limited experience in single-engine IFR air transport, both at a flight operations, management and maintenance level. In Kirkhope Aviation’s case, engaging the assistance of another ASETPA/PSEA operator as well as people with expertise in airworthiness management, allowed us to plug our own expertise gap, which ensured a relatively seamless approval.

A safe and capable platform

At the end of the journey, our Cessna Grand Caravan EX sits alongside our multi-engine fleet capable of doing the same roles, often with better payloads and into shorter strips. Some routes require relatively minor modification to remain PSEA compliant; however, for the most part, PSEA operations become indistinguishable from any other IFR air transport operation.

Despite Seair Pacific being a long-established C208 operator, Kirk Campbell welcomes the ever-increasing uptake by the rest of the aviation industry. ‘I think it’s really positive that PSEA operations are continuing to grow, and operators are transitioning from operating older piston twin-engine aircraft for the much more modern and capable single-engine turbines,’ he says.

This mirrors my experience with clients and guests. Despite reservations about how guests would receive one propeller instead of 2, the response to a single-engine aircraft like the Caravan has been overwhelmingly positive, even without a full appreciation of how risk-managed the operation is.