When Alan Silva, CASA’s Principal Airworthiness Engineer, arrived at work on a morning in November 2024, it began as a quiet day.

The engineering branch of CASA is a generally hushed and learned place where staff study drawings and tables on computer screens with monastic intensity. Messages are exchanged with technical sages and gurus from around the world and their replies meditated upon, under the conflicting imperatives to act quickly but also be sure. All in a day’s work.

This day’s work became urgent for Silva. A routine oversight inspection by CASA had discovered a maintenance organisation had been calibrating its cable tensiometer annually, as it should, but for several years had not replaced the calibration card in the instrument’s case. (A calibration card is only valid in the time interval between calibrations.) This had rendered the calibration meaningless. The failure was significant because a tensiometer is the tool used to adjust aircraft control surface cables to the correct tension, or tightness. An incorrect reading could potentially lead to dangerous flutter of a control surface.

An incorrect reading could potentially lead to dangerous flutter of a control surface.

‘The calibration was done every year, but this laminated sheet inside the box with the unit was never updated,’ Silva says. ‘The expiry date on the sheet was 2007.’

The calibration card is important because very few mechanical instruments measure with complete accuracy in real world use. Because accuracy is essential, these instruments are tested against laboratory instruments known to be accurate. Some instruments can be readjusted back to acceptable accuracy. For others, a calibration card is compiled, showing the difference between the instrument’s readings and the true value being measured or applied.

Dealing directly with the maintenance organisation, which was fully cooperative, CASA surveillance had established the instrument had been used 45 times and that 5 aircraft were affected. Silva set to work, calculating how to compare the actual tension the mis-calibrated instrument would have applied to the control cables of the aircraft, with the range of acceptable control cable tensions published by the aircraft manufacturers. CASA sent Silva’s methodology back to the maintenance organisation for it to do its own checks.

Control cable tension is a subtle but important factor in airframe safety, Silva says.

‘If there’s too much tension, it creates too much stiffness in the controls which affects the rate of return of the control surface to neutral after a control from the pilot input ceases. A flight test must verify, when you let go of the wheel or the stick, how quickly it returns to central. This has to happen at a certain rate and in a certain time period within a defined airspeed range.’

Over-tight cables can wear pulleys and guides more quickly. ‘And the cable can fatigue more, because they actually move internally.’

The control cables also have a damping effect on the control surface and, if that is removed, the control surface may flutter if its mass balance is not precise. Rudder or elevator flutter has been known to detach these control surfaces and aileron flutter, for example, can impose very high torque loads on the outer wing that detach it. In the worst extreme, the pilot will lose control of the aircraft within seconds.

What gets calibrated

Instruments and tools require calibration, including cable tensiometers, torque wrenches and torque screwdrivers, vernier callipers, micrometers, insulation testers, gas detectors, data loggers, scales and feeler gauges. This is because variations in temperature and humidity over time, as well as simple wear and tear, eventually and inevitably affect accuracy, as can rough handling or accidentally being dropped.

CASA Advisory Circular 21-35(1.1): Calibration of inspection and test equipment, lays out why calibration is important. ‘An out of tolerance finding results in a degree of uncertainty that all components or aircraft systems whose determination of being either serviceable or conforming was dependent upon that test equipment were actually within tolerance.’

Silva saw this effect firsthand when he worked as an engineer for an international airline.

Over-tight cables can wear pulleys and guides more quickly.

‘When I was working in the professional area tech services, one of the quality and safety people came up and said, “We just ran a report and the guys have been using this particular torque wrench, which is out of its calibration date”,’ he says. ‘And when the torque wrench went for calibration, it turned out it that required adjustment.’

The airline had good record keeping and knew what aircraft and what jobs it had been used on. ‘It was a case of going into the aircraft maintenance manual and comparing the specifications with the worksheets,’ Silva says.

He also called the operations department to locate the aircraft. One was in Los Angeles but luckily a spare aircraft was on hand to operate its scheduled flight while it was towed to the hangar for urgent reinspection. The incident was expensive but, from a passenger point of view, invisible.

Silva says some modern electronic instruments and tools stay calibrated better than earlier analogue models. ‘The reliability of digital equipment is extraordinary – usually no change or drift over the years.’ CASA has granted exemptions to calibration rules to organisations that have been able to demonstrate that certain instruments or tools have shown no drift over the years. Electronic instruments are often more expensive than their analogue equivalents. Australian specialist tool supplier Henchman quotes an electronic tensiometer at about $2,700, twice the price of a basic analogue model.

Catching the drift

As the Flight Safety Foundation defines it, procedural drift refers to the continuum between textbook compliance and how a procedure is being performed in the real world. The term is related to the concept of organisational drift and is usually used in discussion of maintenance procedures.

It’s instructive that the drift in an unreliable tensiometer took place in an organisation that took safety and procedural compliance seriously. Even so, at some point a small piece of the safety picture – obscure because it related to a tool that was not used in everyday activities – went missing and no-one noticed.

The tensiometer’s lack of calibration was to use the often mocked, but useful classification quoted by US Secretary of Defence Donald Rumsfeld, an ‘unknown unknown’. The maintenance organisation was unaware of what it didn’t know.

But Rumsfeld’s unknown unknowns can be the shadows of other broader factors that are known, or at any rate knowable. These include personnel change and the exodus of knowledge that can accompany it, pressure of work and lack of time, shiftwork, handover and fatigue. This case serves as a reminder of the importance of managing the risk of procedural drift – keeping things as they were meant to be. This requires both a detailed curiosity and a willingness to accept uncomfortable discoveries, such as an engineer, or even an apprentice, pointing at the calibration card and saying, ‘what’s this for?’

Calibrating the lessons

First, calibration is a requirement for a reason. ‘Bosses and bean counters may say it’s a cost because calibration is usually an annual thing, but it has to be done for accuracy,’ Silva says.

Second, understand that calibration means different things for different tools and instruments. Some can be reset to accurate standards; for others, index cards are used to show the difference between the device’s readings and the actual measurements.

Third, the procedures for calibration and use should be made explicit. Knowledge here rests with calibration centres, but advice on correct use of the calibrated instrument or tool is part of the service.

It doesn’t always go smoothly: flutter

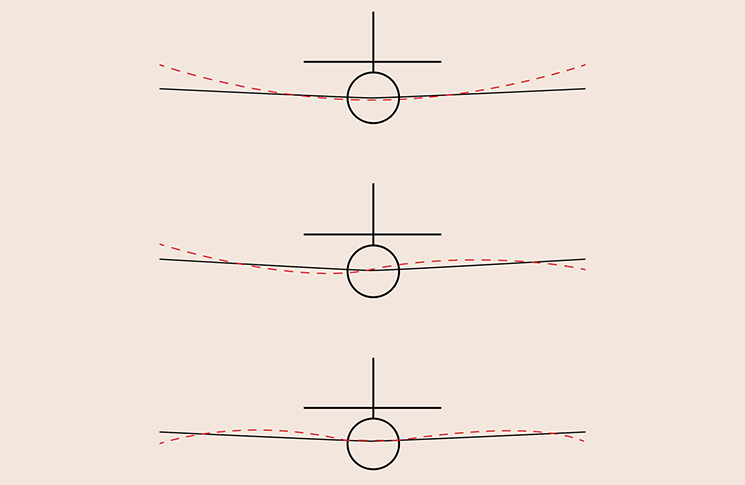

In an ideal world, airflow over wings and control surfaces is smooth. In the real world, the interaction of structural elasticity (the tendency for a structure, like a wing, to return to its original shape when a force acting on it is removed) with aerodynamic and inertial forces can create flutter.

Flutter is a resonance effect where, at certain speeds and conditions, oscillations of parts of an aircraft are amplified by the passing air, and get larger, as they approach the natural resonant frequency of the part (the frequency of vibration it would produce when struck – think of a bell). This can lead to damage and loss of control. Flutter can happen to movable control surfaces, or to entire wing and tail surfaces and, if severe, can detach any or all of these.

Flutter is different to aerodynamic buffeting, which happens when airflow breaks away from a wing or tail at a high angle of attack. Unlike buffeting, flutter amplifies itself and becomes destructive. Flutter is one of the reasons aircraft have a maximum speed VNE and a maximum smooth airspeed VA.

Design defences against flutter include making wings and control surfaces as stiff as possible (the example of a flapping flag shows how flutter is inversely related to material stiffness). Flat or concave control surfaces resist flutter better than slightly convex ones. And control surfaces are balanced so the mass forward and aft of their hinge points is equal. Free play in control surfaces makes them vulnerable to flutter and should be minimal.

The goal of aircraft designers is to have the resonant frequency for any part of the aircraft to occur only at airspeeds faster than VNE – but gusts can produce this frequency at lower airspeeds when they push the indicated airspeed higher. This is why transport category aircraft have a design speed Vb for flight in turbulent conditions.

The fortunate few who have survived an encounter with control surface flutter often describe a buzzing noise, as the surfaces oscillate. The response that saved them is the same in each case: level the wings, reduce power and gently raise the nose to reduce airspeed.