The challenge of partial instrument failure

Limited panel instrument flying is a key part of every instrument proficiency check, but a recent incident highlights the challenges that real-world instrument failures bring.

Limited panel instrument flying is a skill that all instrument-rated pilots have been taught and tested on, but one that most rarely consider outside the context of the annual or biennial proficiency checks. Despite this, actual limited panel flying is a difficult proposition with a chequered history, both in this country and overseas.

Recognising failure of directional instruments is a key part of the instrument rating syllabus – CASR 61 MOS Schedule 2 – IFL.1. Few aircraft have the ability to intentionally fail primary instruments like the artificial horizon or directional gyroscopes, presenting a challenge for training this on actual aircraft.

Instructors typically initiate simulated limited panel flying by masking the ‘failed’ instrument with paper. Excellent for teaching someone to fly on a limited panel, but less so for teaching them to recognise and manage the subtle signs of a genuine instrument failure.

Adding to this difficulty is the glass cockpit – integrated avionics often overlay instruments upon one another. ‘Simulated’ limited panel is often achieved by ‘disabling’ one display, prompting the student to activate a reversionary mode and use the full instrument set, albeit on a secondary display.

Simulators can bridge the gap but, again, not without limitation. Flight simulation training devices (FSTDs) are an approved and integral part of instrument training, allowing not only a cost-effective means of delivering training but also with higher fidelity over failure modes.

Unfortunately, even with high quality FSTDs, there remain specific faults and indications that aren’t possible to simulate. Layered over this is the difference between the equipment pilots complete training on and the equipment they eventually use in larger aircraft, including the interconnect between systems.

A recent limited-panel incident highlights this disconnect.

Round in circles

Beechcraft C90A VH-JEO, 25 January 2024, Kalgoorlie WA

A Beechcraft C90A was conducting an IFR flight operating under CASR Part 135 (Air Transport – Smaller Aeroplanes) from Kalgoorlie to Warburton, Western Australia. About half an hour into the flight, while operating on autopilot in IMC and deviating around storm activity, the aircraft commenced an uncommanded turn to the right. The turn was a result of the horizontal situation indicator’s (HSI) heading source failing, which also integrated with the autopilot.

In response, the pilot disengaged the autopilot and repositioned the aircraft back onto the correct heading, deviating from the assigned altitude in the process. Having observed the aircraft deviate laterally and vertically, the monitoring air traffic controller queried the pilot’s intentions several times. The combination of manually flying in IMC, troubleshooting and the interactions from ATC compounded an already high workload situation for the pilot.

The pilot elected to return to Kalgoorlie and the aircraft landed around 0800 local time.

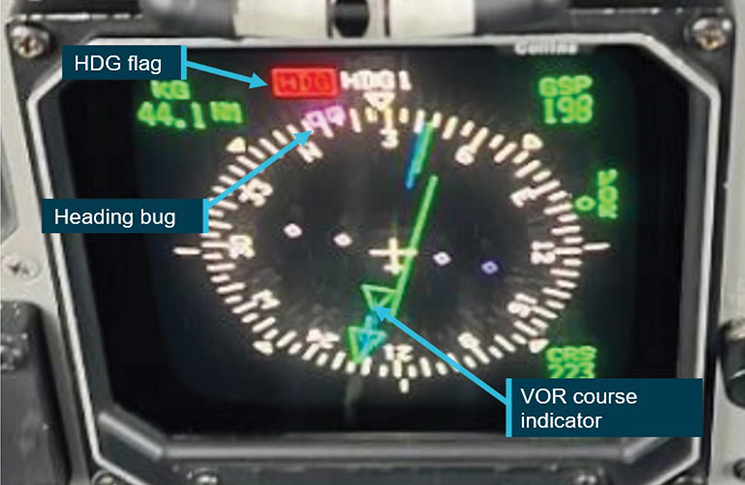

Subsequent investigation revealed the heading source for the pilot’s HSI had failed; this is displayed in flight as a red HDG flag on the instrument, but no aural warning or master warning annunciator was associated with this type of failure.

The pilot had 1153 hours total experience and 144 hours on type.

Recognising failure

A common theme in these types of incidents is that they occur when pilots are under significant workload. This often leads to a delayed realisation that their attitude or directional references may be unreliable. Partial, unflagged failures can make this challenge even more difficult.

Even with the complete failure of gyro instruments, older cockpits may provide no aural warning or conspicuous annunciator for the failure. Modern cockpits may annunciate this more clearly, such as the Beechcraft C90’s HSI displaying a red flag. But again, it may not be immediately recognised by the crew.

Given the difficulty in realistically training for these failure scenarios on aircraft, systems knowledge becomes key to quickly recognising and responding. Older cockpits can present this information in a relatively ad-hoc fashion and, therefore, familiarity with the aircraft you are flying is critical.

Ask yourself:

- How will I know if the suction or pneumatic sources have failed?

- Is there an annunciator that will tell me?

- How low is too low on the suction gauge?

- How do my primary instruments indicate failure?

- Do they have a failure flag or light?

- How does a toppled attitude indicator or directional gyroscope behave?

- Which of my primary instruments are vacuum powered and which are electrically powered?

- Do any have an integrated backup power source?

- How long does the backup power source last?

Understanding where your autopilot receives its data from is also important. VH-JEO’s autopilot received its heading data from the same reference as the pilot’s HSI. For this reason, the pilot operating handbook for the aircraft provided guidance against using the autopilot after failure of the HSI heading function. Other systems may have standalone data sources that are integrated into the autopilot system.

It’s rare that the failure is immediately recognised and understood.

On the incident flight, the pilot’s attempts to continue utilising the autopilot likely contributed to high workload and further deviations from track and altitude, something they wouldn’t have done if that system had been more thoroughly understood.

Integrated avionics

Newer glass cockpits with integrated avionics, such as the Garmin G1000, display failure modes in a more intuitive fashion. Almost all of these systems display a large red cross through a failed instrument, removing confusion as to the validity of that information.

Recognising the failure is intuitive, but the next steps may be less so. The aircraft flight manual will guide you here. Most avionics set-ups will have some sort of reversionary mode, allowing you to select the backup data source for that instrument. For G1000NXi units, this is buried within the PFD Options and then sensors softkeys on the PFD.

Source: ATSB Investigation Report AO-2024-003

Although many systems will automatically switch to backup instruments following failure, understanding how to manually make this change is critical in the case that it doesn’t, such as a partial failure.

Partial failures are not emphasised in training and present the pilot with an array of choices and decisions that have to be made relatively quickly.

In the G1000NXi, 2 other sensor warning modes exist – miscompare and no compare. Similar warnings exist on most integrated avionics platforms. My experience is that neither warning is well understood, and misinterpreting what these warnings tell you can be as disorientating as an outright failure.

Miscompare

Miscompare is an indication there is a disagreement between the primary and secondary instruments.

The example above indicates a heading miscompare on the Garmin G1000NXi triggered when the 2 heading sources disagreed by more than 6 degrees. Similar warnings are possible for pitch and roll data on the attitude indicator, as well as indicated airspeed and altitude.

Importantly, because neither instrument has outright failed, there is no clear indication of which source is correct. The pilot must determine which source is valid using other instruments and broad situational awareness.

No compare

No compare, on the other hand, indicates the sensor data is missing from the other source – notionally failure of that other sensor.

Awareness and training

It would be nice to be able to end articles like this with a neat tagline as a panacea to the problem. Unfortunately, limited panel is a dynamic and complex challenge, presenting unexpectedly and with unforeseen consequences. Like many things that we don’t have a cure for, awareness is sometimes the next best thing.

The operator of VH-JEO introduced training on the aircraft with a workaround to replicate the failure mode for its pilots – unslaving the HSI from its heading source using a switch in the cockpit. While not perfect, rehearsing a response still offers a solid foundation for managing an actual emergency. This preparation helps pilots respond more effectively when a genuine failure occurs.

Explore the limitations of your instruments and understand the way in which their failure will present. It’s unlikely to be exactly what you expect, but more likely to be a worse challenge than the complete, immediate failures you would be focused on as part of your instrument rating.