What becomes of aviation in a world committed to carbon neutrality? The answer might not be as grim as it seems, with new technologies and fuels rapidly developing

The burning issue

You only had to pick up a newspaper this week, to know that fossil fuel’s ‘Berlin Wall’ had finally collapsed. Andrew Forrest, October 2021

Powered flight and the internal combustion engine are contemporaries, like cousins. The petrol engine’s combination of high power and light weight made the seemingly miraculous act of heavier-than-air flight possible in a way that the steam engines powering Felix du Temple’s 1874 monoplane and Clement Ader’s bat-like 1890 Éole aircraft could not.

But every aircraft piston engine since the Wright brothers’ self-developed powerplant for the 1903 Flyer I, and every gas turbine since Frank Whittle’s barely controllable bench test model of 1937, has added something to the Earth’s atmosphere: carbon dioxide (CO2), a gas once thought of as benign, since it is only toxic to human beings at high concentrations, but a proven major contributor to the sudden warming of the Earth’s climate.

While aviation is not the largest contributor to increased CO2 levels, it is among the fastest growing CO2 sources.

- Industry body the Air Transport Action Group says air travel contributes to about 2 per cent of global CO2 emissions, and 12 per cent of transport emissions.

- The Environmental and Energy Study Institute, a bipartisan body drawn from the US Congress, says passenger air travel is producing the highest and fastest growth of individual emissions, despite a significant improvement in efficiency of aircraft and flight operations over the past 60 years.

- In 2019 the International Council on Clean Transport said aviation emissions were growing at 5.7 per cent a year, a figure 70 per cent higher than those used to develop the International Civil Aviation Organization’s (ICAO) projections that CO2 emissions from international aviation would triple under business as usual by 2050.

Air transport does not have the option of ignoring its greenhouse gas emissions. In an attempt to control emissions growth, ICAO has created a market-based offsetting scheme. Offsetting involves taking other measures, such as planting vegetation or protecting wilderness areas, in order to allow plants to absorb atmospheric CO2. The Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) was adopted by 221 ICAO member states in 2016 and commenced in 2019. Its stated goal is to cap carbon emissions from international aviation at 2020 levels.

Airline offsetting requirements under the CORSIA are voluntary from 2021–2026, with mandatory offsetting requirements commencing from 2027 for most nations. Australia and 80 other ICAO member states (representing over 76 per cent of international aviation) have volunteered to participate in the offset requirements of the scheme from 2021.

The cost of doing nothing for air transport could be stark. In April 2021 France banned domestic flights between cities with a train connection of less than 2.5 hours. But several alternatives are fast emerging, bearing out environmentalist Bill McKibben’s 2006 observation that for climate change, ‘there are no silver bullets, only silver buckshot’.

Electric dreams: power, performance, cost

General aviation is a bit player in the drama of global emissions reductions. The US General Aviation Manufacturers’ Association estimates that, in the US, which has the world’s largest general aviation fleet, greenhouse gas emissions from general aviation account for less than 0.2 per cent of overall emissions.

However, piston-engine aircraft, which developed in parallel with the automobile, may follow it into electric propulsion. Current battery powered aircraft such as the Pipistrel Alpha Electro trainer are small and low performance types, characterised by very low direct operating costs ($A3 an hour in ‘fuel’ for the Alpha electro). But continual evolution of battery and motor technology is showing potential to change this.

Batteries are getting cheaper and more powerful.

Batteries are getting cheaper and more powerful. A March 2021 study published in Energy & Environmental Science found the real price of lithium-ion cells, scaled by their energy capacity, had declined by about 97 per cent since their commercial introduction in 1991. Other research found battery costs had fallen almost tenfold since 2010 which, admittedly, represents a tapering of their steep initial price drop.

The other possible economic driver for electric aircraft adoption is their greatly reduced engine maintenance. A 2021 report from the US Department of Energy’s Argonne National Laboratory found electric vehicles cost 41 per cent less in maintenance costs per kilometre than similarly sized internal combustion engine vehicles. Swedish startup manufacturer Heart Aerospace, which is developing a four-motor 19‑seat short-range regional airliner, says its ES‑19 will have a similar acquisition price and offer direct operating costs (energy and maintenance) 50 to 70 per cent lower than competing fossil fuel-powered aircraft. Maintenance costs will drop by 90 per cent, compared to turboprops, Heart says.

It says electric propulsion is viable for short-haul airline operations, which it says account for 40 per cent of worldwide aviation CO2 emissions. The ES‑19 has a projected range of 400 km (216 nm) and is planned to be certified by 2026.

The third advantage of electric propulsion is hinted at by the Heart ES-19’s 4-motor configuration, and more thoroughly demonstrated by the NASA X-57, scheduled to have flown in February 2022. Electric motors allow for distributed propulsion, in which the same volume of thrust can be provided with equal efficiency by a few large motors or more small ones. Distributed propulsion also allows aircraft wings to be optimised for efficient high-speed flight and ‘blown’ by leading edge mounted motors to create extra lift for the low‑speed phases of take-off and approach.

Waste not want not? Biofuels

Heart Aerospace is unambiguous about the limits of electric propulsion. ‘Electric aircraft will not be viable for long-haul routes anytime soon, and therefore, it is only part of the solution for decarbonising air travel. Hydrogen and biofuels can be looked to for these applications,’ the company says.

However, the projections on biofuels, made from crops or recycled materials, are not as optimistic as those for battery power.

The British Jet Zero Council, a government and industry body investigating clean propulsion options for aviation, found the costs of sustainable aviation fuels (SAF) were high and uncertain, with ‘a wide range of estimates … as to what the future uptake of SAF could look like’.

The Jet Zero Council quoted an International Council on Clean Transportation report which found, in general, SAFs were around 2 to 3 times the cost of kerosene, and potentially up to 8 times the cost of kerosene, for certain types such as alcohol-to-jet. The ICCT found used biofuel, derived from used cooking oil, is currently the most cost-effective alternative jet fuel, followed by ‘gasification of municipal solid waste and lignocellulosic feedstocks’. The World Economic Forum Clean Skies for Tomorrow report suggests biofuel production costs could fall by 20–70 per cent by 2050, depending on the fuel type, due to economies of scale and reductions in the cost of input feedstocks.

An elementary solution? Hydrogen

Hydrogen, the lightest of the elements, is the most abundant substance in the universe. It is colourless, odourless, non-toxic and highly flammable. Hydrogen is not, strictly speaking, a fuel because it does not exist in pure form on earth and refining it from compound materials such as water (H2O) uses more energy than the resulting hydrogen provides. Traditionally produced hydrogen made by steam reformation of hydrogen-containing gases is not a green fuel because the process involves using fossil fuels and releasing CO2 into the atmosphere.

But the notion of using cheap and abundant solar electricity to produce hydrogen which would then become, in effect, an energy store and carrier, is taking off. Mining entrepreneur Andrew Forrest is behind Fortescue Future Industries, which aims to produce hydrogen using solar power and export it as energy to the world. In a speech to the National Press Club, Forrest said Australia had ‘thousands of times more renewable energy reserves than fossil fuel reserves’ and predicted the cost of solar electrolysis-produced ‘green’ hydrogen would halve in 5 years. At least 6 multibillion dollar green hydrogen projects are underway in Australia, (see breakout) including one with more electricity generating power than all Australia’s coal-fired power stations.

Hydrogen can produce mechanical energy in several ways. It can be used in jet or piston internal combustion engines (a process which was first demonstrated in 1806) or converted into electricity in a fuel cell (first demonstrated in 1839).

Hydrogen’s weakness as a transport fuel is its lightness and bulk as a gas, which requires extreme compression and cooling to create a more compact liquid form, or storage as part of a chemical compound. Hydrocarbon fossil fuels are one such compound. They provide the energy density that has made aviation possible, at the cost of CO2 emissions.

The high price of producing e-kerosene makes it suitable only as an aviation fuel, where power-to-mass ratio is critical.

Plucked from the air: e-kerosene

Hydrocarbon fuels can be mined, drilled for, or made. Synthesising hydrocarbon fuels is nothing new. Nazi Germany used a combination of heat and pressure called the Fischer-Tropsch process to produce about 9 per cent of its liquid fuel needs from coal in World War II. The innovation is in making synthetic kerosene using renewable energy, which makes the fuel carbon-neutral. This is done by combining green solar electrolysed hydrogen (H) with carbon dioxide (CO2) from the air, and is known by a number of terms such as ‘e-fuel’, ‘synthetic kerosene’, ‘synfuels’ and ‘power-to-liquid’.

A briefing by renewable energy pressure group Transport & Environment notes that the high price of producing e-kerosene makes it suitable only as an aviation fuel, where power-to-mass ratio is critical. It recommends e-kerosene be blended with fossil fuels to reduce their greenhouse emissions. The price of e-kerosene may fall with widespread mandatory adoption, it predicts. ‘Some reports suggest, under the right conditions, e-kerosene can reach price parity with taxed fossil kerosene by the 2030s, others later,’ the briefing says. Transport & Environment notes the non-CO2 emissions of e-kerosene, such as soot and nitrogen oxides, remain similar to those of fossil fuels.

Fertile possibilities: ammonia in aircraft

Another possible hydrogen storage and transport compound can be found in your kitchen cupboard: ammonia.

Ammonia consists of 3 hydrogen atoms bonded to a nitrogen atom (NH3). The most commonly produced chemical substance, it is used in almost all fertilisers and in many industrial applications. Pure ammonia can be stored as a liquid under pressure and in this state is known as anhydrous ammonia. Ammonia storage and transport is a well-developed industry, owing to its use as an ingredient of fertiliser and industrial processes. It has been produced by combining electricity, water and nitrogen from the air since 1913 by the Haber-Bosch process.

Ammonia is:

- gaseous at room temperature – its boiling point is -33.34 degrees

- stored by compression to 8x atmospheric pressure – a similar storage profile to liquid petroleum gas (LPG)

- ‘cracked’ or decomposed by heating before use as a fuel

- about half the energy density of fossil fuels at 6kW/kg.

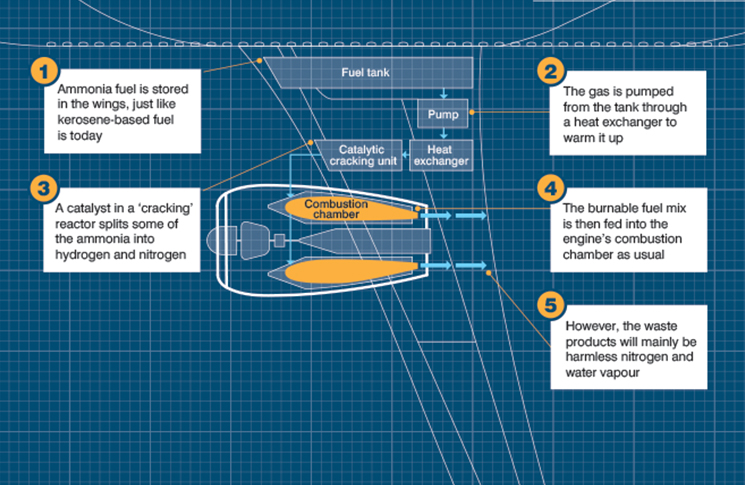

British Aerospace company Reaction Engines is pursuing development of ammonia as a jet fuel. It proposes cracking the ammonia fuel in flight, using heat exchangers (a Reaction Engines specialty) to create a zero‑carbon fuel blend of ammonia and hydrogen that burns like jet fuel.

James Barth, engineering lead at Reaction Engines, says, ‘Our study showed that an ammonia-fuelled jet engine could be adapted from currently available engines, and ammonia as a fuel doesn’t require a complete rethink of the design of civil aircraft as we know them today. This means a fast transition to a sustainable aviation future is possible at low cost; ammonia-powered aircraft could be serving the world’s short-haul routes well in advance of 2050.’

British Aerospace company Reaction Engines is pursuing development of ammonia as a jet fuel.

The shades of hydrogen:

|

In the pipeline: Hydrogen projects

|

Surprised there is no mention of the Bye Aerospace eFlyer 2 which is the worlds first FAA 14 CFR Part 23-Type Amendment 64-Certified Applicant for a “Normal Category” Electric Aircraft. This is being followed by a 4 seater eFlyer 4 and an 8 seater eFlyer 800. All are entirely new designs with Aerodynamic efficiency being twice that of a typical aircraft of similar size.

very clear and good article easy to understand. Thank you